|

| Kinetrol P3 On/Off Positioner |

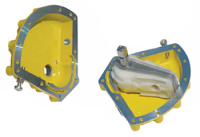

The Kinetrol P3 On/Off positioner consists of an electronic positioning circuit mounted in a robust all-metal enclosure, which controls a 1⁄4-turn rotary pneumatic actuator via standard on-off solenoid valves direct-mounted on the actuator’s own interface.

The P3 circuit is designed so that its assembly can be mounted inside a standard Kinetrol limit switch box (either ULS-type, or explosion proof XLS-type), using only two screws. The P3 assembly is complete with feedback potentiometer and anti-backlash gear drive, which engages with gear teeth on the limit switch coupling to read the actuator’s position. The limit switch coupling complete with gear teeth needs to replace the standard coupling if a standard box is being retrofitted with a P3.

The positioner circuit is powered by the mid-point input voltage. It functions by comparing the actual mid-point position (read by the feedback potentiometer) with the set position (set via an on-board preset, or a remote preset, or a remote 4-20mA signal). The positioner circuit uses its solid-state switched outputs to power solenoid valves which drive the actuator towards the position where the set position corresponds with the actual position. When it gets there, the solenoids are switched to hold that position.

The positioner circuit incorporates a unique power supply allowing it to be powered by any of 24vDC, 48vDC, 115vAC or 230vAC, 50/60 Hz, without the need for any change. The supply maintains full isolation of the low voltage control circuit from the power input line (up to 5Kv). Switching of the solenoid valve outputs is achieved through opto-isolated solid state switches which operate at all the above voltages – only the solenoid coils themselves need to be adapted specifically to the supply voltage. The use of solid state switching avoids any limitations on relay contact life.

Double acting models are available as fail-free (standard), fail-down (moves clockwise on loss of electrical power if air supply is still present) and fail-hold (holds position on loss of electrical and / or air supply) variants. Spring return models move in the direction of the spring on loss of electrical failure, but hold position on loss of air. An external pressure switch (which cuts electrical power on loss of air pressure) should be fitted by the customer if spring function is required on loss of air and / or electrical power.

An optional angle retransmit (AR) circuit can be retrofitted by plugging it into the top of the positioner circuit and fixing with three screws. The AR circuit is a 2-wire loop-powered 4-20mA device, which reads the position of the positioner’s feedback pot. It is fully functional whether or not the positioner circuit is powered, and the feedback signal is electronically isolated (ie. floating) relative to the low voltage positioner circuit (which in turn is electrically isolated from the power supply and solenoid connections).

Extra solid-state switches have been incorporated on the positioner board to allow supply to both solenoid valves via a single cable for movement to the upscale position when the positioner is in spring-return or fail-down mode, while still allowing the positioner to control the two valves independently for the mid position. If the mid-position input is energised, then these extra switches isolate the solenoids from the upscale/downscale inputs.

The three power input lines (for up, mid, down positions) are independently fused using plug-in miniature fuses on the positioner circuit board.

External connections are made via a multi-option connector board, which allows simultaneous connection of up to four changeover limit switches, three control supply inputs plus neutral/negative, and a single low-voltage signal. This connector board, like the positioner circuit assembly, mounts in either the standard ULS or XLS box using two screws.

If an angle retransmit circuit is fitted using the low voltage signal terminal, optional 4-20mA inputs or external setpoint pot wires can be connected either directly to the terminal block on the positioner circuit or, if only three or less limit switches are in use, relayed through an unused limit switch terminal on the connector board.

The limit switch box is fitted with a ground terminal which must be connected to a suitable external ground.

Industrial solenoid valves which permit the use of standard quality air supplies (instrument quality air is not required) are direct-mounted on adaptor blocks on the side of the actuator, and electrically connected via steel-armoured flying leads with DIN sockets on the solenoid end. At the positioner end, they connect to two 2-way terminal blocks on the circuit board. A range of solenoid valve options are available, determined by the function required, the supply voltage, and whether or not the unit requires hazardous area certification.

The positioner circuit is powered by the mid-point input voltage. It functions by comparing the actual mid-point position (read by the feedback potentiometer) with the set position (set via an on-board preset, or a remote preset, or a remote 4-20mA signal). The positioner circuit uses its solid-state switched outputs to power solenoid valves which drive the actuator towards the position where the set position corresponds with the actual position. When it gets there, the solenoids are switched to hold that position.

Need More Information?

Contact Kinetrol USA at

or call 972-447-9443.

The positioner circuit incorporates a unique power supply allowing it to be powered by any of 24vDC, 48vDC, 115vAC or 230vAC, 50/60 Hz, without the need for any change. The supply maintains full isolation of the low voltage control circuit from the power input line (up to 5Kv). Switching of the solenoid valve outputs is achieved through opto-isolated solid state switches which operate at all the above voltages – only the solenoid coils themselves need to be adapted specifically to the supply voltage. The use of solid state switching avoids any limitations on relay contact life.

Double acting models are available as fail-free (standard), fail-down (moves clockwise on loss of electrical power if air supply is still present) and fail-hold (holds position on loss of electrical and / or air supply) variants. Spring return models move in the direction of the spring on loss of electrical failure, but hold position on loss of air. An external pressure switch (which cuts electrical power on loss of air pressure) should be fitted by the customer if spring function is required on loss of air and / or electrical power.

An optional angle retransmit (AR) circuit can be retrofitted by plugging it into the top of the positioner circuit and fixing with three screws. The AR circuit is a 2-wire loop-powered 4-20mA device, which reads the position of the positioner’s feedback pot. It is fully functional whether or not the positioner circuit is powered, and the feedback signal is electronically isolated (ie. floating) relative to the low voltage positioner circuit (which in turn is electrically isolated from the power supply and solenoid connections).

Extra solid-state switches have been incorporated on the positioner board to allow supply to both solenoid valves via a single cable for movement to the upscale position when the positioner is in spring-return or fail-down mode, while still allowing the positioner to control the two valves independently for the mid position. If the mid-position input is energised, then these extra switches isolate the solenoids from the upscale/downscale inputs.

The three power input lines (for up, mid, down positions) are independently fused using plug-in miniature fuses on the positioner circuit board.

External connections are made via a multi-option connector board, which allows simultaneous connection of up to four changeover limit switches, three control supply inputs plus neutral/negative, and a single low-voltage signal. This connector board, like the positioner circuit assembly, mounts in either the standard ULS or XLS box using two screws.

If an angle retransmit circuit is fitted using the low voltage signal terminal, optional 4-20mA inputs or external setpoint pot wires can be connected either directly to the terminal block on the positioner circuit or, if only three or less limit switches are in use, relayed through an unused limit switch terminal on the connector board.

The limit switch box is fitted with a ground terminal which must be connected to a suitable external ground.

Industrial solenoid valves which permit the use of standard quality air supplies (instrument quality air is not required) are direct-mounted on adaptor blocks on the side of the actuator, and electrically connected via steel-armoured flying leads with DIN sockets on the solenoid end. At the positioner end, they connect to two 2-way terminal blocks on the circuit board. A range of solenoid valve options are available, determined by the function required, the supply voltage, and whether or not the unit requires hazardous area certification.

KEY FEATURES

- Robust modulating actuator, control tolerant of standard air quality (instrument air quality is not necessary).

- Three position rotary control using only three electrical inputs plus air supply.

- Two endstop positions + adjustable mid position anywhere in angular range of actuator (90 or 180°).

- Control circuit mounts inside standard all metal industrial quality Kinetrol ULS or XLS limit switch boxes without disturbing limit switches – available fully assembled, or (on non-explosion proof models only) for user retrofit to existing boxes.

- Direct mounting onto full range of Kinetrol 1⁄4 turn actuators. Namur mounting options available.

- Uses direct-mounting standard solenoid valves outside box to position actuator.

- Easy adjustment of mid position set point by switch–selectable choice of methods: on-board pot, remote pot or 4-20mA input signal.

- Explosion proof options available (approved to IECEX, ATEX; FM (for USA & Canada) standards pending) by use of XLS housing plus standard explosion proof solenoid valves.

- All new positioner circuit – runs on any of 24vDC, 48vDC, 115vAC or 230vAC power without any change required.

- Solid-state universal-voltage solenoid switching – no mechanical contacts.

- Three separate on-board mains fuses for three inputs.

- Switchable selection of mid-point setting method (on-board preset, remote preset, remote 4-20mA signal).

- Switchable selection of double acting or spring return operating mode.

- Power input isolated from signal inputs and outputs for all voltage options.

- Moulded reinforced plastic internal circuit cover for insulated safety.

- Positioner has user-adjustable zero, span, deadband and damping parameters via preset pots for easy optimization of positioning performance.

- Damping parameter gives velocity-proportional setpoint advance to allow better stabilization of fast-moving or high inertia loads while maintaining resolution and repeatability.

- Retrofittable isolated loop-powered 4-20mA angle-retransmit circuit available – just plugs in inside same enclosure – with its own user-adjustable zero and span presets.

Need More Information?

Contact Kinetrol USA at

www.kinetrolusa.com

or call 972-447-9443.