|

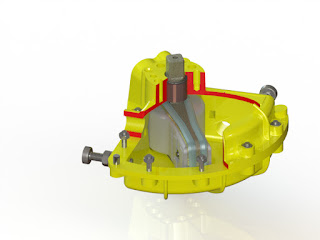

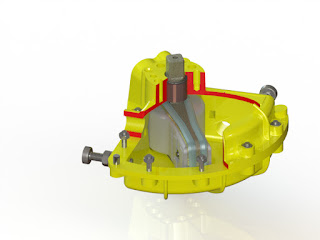

Internal view of vane actuator. Note the

single piece vane/shaft design. |

Rack and pinion and scotch yoke type pneumatic actuators depend on gears to transfer torque and movement, while integral vane-shaft actuators have no gears (or linkages). As a result,

integral vane-shaft actuators are the hands-down choice for high cycle rate and modulating valve/damper actuation.

Why? Because of the mechanical problems inherent to the use of gears.

According to

Wikipedia,

"A gear or cogwheel is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part to transmit torque."

The primary disadvantages to gears are:

- Friction

- Fretting Wear

- Backlash

When gears mesh, there is friction. Friction causes heat and wear, which effects the mechanical life of the actuator. Friction converts kinetic energy into thermal energy and can have dramatic consequences if left unchecked. Another important consequence of friction is wear, which may lead to performance degradation and/or damage to the internal components of a rack and pinion or scotch yoke actuator.

"Fretting wear" is caused by the repeated cyclical rubbing between two surfaces (gears in the case of scotch yoke or rack and pinion actuators) and over a period of time, will remove material from one or both surfaces.

Backlash happens when gears change direction. It is caused by the gap between the trailing face of the driving tooth and the leading face of the tooth behind it. The gap must be closed before force can be transferred in the new direction, hence the phenomena of backlash. This is also sometimes referred to as "slop".

For pneumatic actuators with very low cycle rates, or ones that are not used for modulating service, internal gears may be acceptable. However, for applications where there are high cycle rates, or require accurate modulation, the use of a single machined vane actuator with integral shaft is preferred. The reason? No friction, wear, or backlash. 100 percent of the movement of the vane is transferred to the shaft without loss or hysteresis.

For any questions about

applying the most appropriate type of actuator for any valve or damper application, call

Kinetrol at

972-447-9443 or visit

http://www.kinetrolusa.com.