|

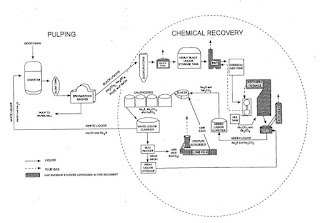

| Simplified Pulp and Paper Process Diagram |

The purpose of the chemical recovery cycle is to recover cooking liquor chemicals from spent cooking liquor. The process involves concentrating black liquor, combusting organic compounds, reducing inorganic compounds, and reconstituting cooking liquor.

|

| Chemical recovery process flow diagram. |

Decanted green liquor is transferred to the causticizing area, where the Na2CO3 is converted to NaOH by the addition of lime (calcium oxide [Ca0]). The green liquor is first transferred to a slaker tank, where Ca0 from the lime kiln reacts with water to form calcium hydroxide (Ca(OH)2). From the slake, liquor flows through a series of agitated tanks, referred to as causticizers, that allow the causticizing reaction to go to completion (i.e., Ca(OH)2 reacts with Na2CO3 to form NaOH and CaCO3).

Equipment used to produce pulp, paper, and paperboard is exposed to a wide range of temperature and humidity conditions, and contaminants. Actuators used in Pulp and Paper manufacturing processes must withstand the most difficult operating conditions. Kinetrol actuators are preferred in these situations because they don't allow corrosive atmospheres to penetrate the actuator or springs, their long cycle life, and their epoxy stove enamel finish.

Equipment used to produce pulp, paper, and paperboard is exposed to a wide range of temperature and humidity conditions, and contaminants. Actuators used in Pulp and Paper manufacturing processes must withstand the most difficult operating conditions. Kinetrol actuators are preferred in these situations because they don't allow corrosive atmospheres to penetrate the actuator or springs, their long cycle life, and their epoxy stove enamel finish.Contact the experts at Kinetrol USA at 972-447-9443 to discuss any pulp and paper mill actuator application.