The history of enduring manufacturing companies reveals a common truth: long-term success does not result from marketing alone or fleeting technological advantage. Instead, it emerges from a steadfast commitment to engineering excellence, precision design, and uncompromising quality control. Few companies illustrate this more clearly than Kinetrol, Ltd of Farnham, England, whose leadership in the pneumatic actuator and ancillary product market has endured for decades.

From its earliest days, Kinetrol embraced the philosophy that engineering precision forms the foundation of reliability. Pneumatic actuators operate in environments where failure can mean costly downtime, safety risks, or impaired process performance. Kinetrol understood that success would not come from cutting corners but from producing actuators that perform consistently in the most demanding industrial applications. By investing heavily in design innovation and rigorous testing, the company built a reputation for actuators that do not quit. That reputation has become one of its greatest assets.

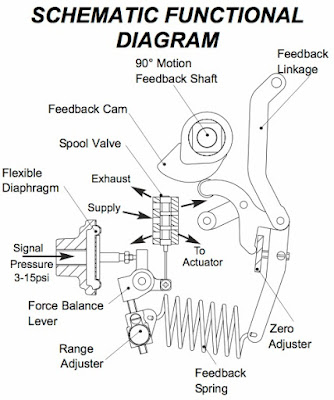

Precision engineering has always been at the heart of Kinetrol’s product line. Every actuator reflects an attention to detail that minimizes wear, ensures smooth operation, and extends service life. The company’s vane actuator design, for example, is recognized worldwide for its simplicity and durability. Unlike complex alternatives that can suffer from mechanical inefficiencies, Kinetrol’s actuators deliver direct, reliable torque with a minimal number of moving parts. This dedication to mechanical elegance stems from a culture that prizes engineering clarity and craftsmanship above expediency.

Quality control stands as the third pillar of Kinetrol’s success. While many manufacturers claim to test their products, Kinetrol built its business model around the principle that every actuator must meet exacting performance standards before reaching the customer. This rigorous oversight does more than protect the Kinetrol brand; it instills confidence in engineers and plant managers who depend on uninterrupted performance. Decade after decade, these customers return to Kinetrol because experience has shown them that the company’s actuators last longer, require less maintenance, and outperform alternatives.

This combination of engineering excellence, precision design, and uncompromising quality has created more than just a line of products. It has built a culture of reliability that industrial clients value deeply. Whether in chemical processing plants, oil and gas operations, water treatment facilities, or food manufacturing environments, Kinetrol actuators continue to prove themselves in real-world conditions. Companies know that by specifying Kinetrol, they are choosing more than a component; they are investing in long-term operational stability.

The industrial landscape has changed dramatically over the decades, but Kinetrol has remained a leader because it has not lost sight of the fundamentals. Many competitors have entered the market, yet Kinetrol continues to thrive because it never compromises on the engineering principles that built its reputation. Innovation at Kinetrol does not mean chasing trends. Instead, it means refining designs, improving materials, and constantly verifying that each improvement serves the larger goal of reliability and performance.

As industries evolve and demands grow more complex, the value of dependable actuation technology becomes even more apparent. In an age where automation drives efficiency, downtime becomes more costly, and safety standards rise ever higher, Kinetrol’s consistent approach stands out. Customers trust the company not only because of its technical expertise but because of its unwavering dedication to delivering exactly what it promises.

For customers in the United States, this legacy of reliability is supported through Kinetrol USA of Plano, TX which sells, supports, and distributes Kinetrol actuators nationwide. American customers benefit from local expertise and service while drawing on the proven engineering strength of Kinetrol, Ltd in England. This partnership ensures that industries across the U.S. have direct access to world-class actuators and responsive support, reinforcing the same values of excellence, precision, and quality control that have made Kinetrol a global leader.

The story of Kinetrol demonstrates that in manufacturing, the companies that endure are the ones that never waver from their core principles. Engineering excellence, precision design, and uncompromising quality control are not slogans for Kinetrol—they are the foundation of its identity and the reason it remains at the forefront of the pneumatic actuator industry.