The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Happy New Year from Kinetrol USA!

All of us at Kinetrol USA wish our customers, distributors, colleagues and friends a very happy and prosperous 2018!

Kinetrol Blueline Pneumatic Actuator - Features

Features of the Kinetrol Blueline pneumatic actuator:

- Durable Blueline coating meets FDA and BfR L1 specifications.

- Corrosion resistant zinc (non-incendive) or aluminum alloy case.

- Easy stop adjustment at each end of stroke for accurate seating.

- Long life epoxy or PTFE internal finish.

- Integral vane/shaft casting - only one moving part.

- Manual override square and position indicator.

- Space filling/energy absorbent sideplates (polymer or metal).

- Double opposed, Polyurethane, lip seals for effective sealing and long maintenance free life.

- Stainless steel expanders ensure long term lipseal / case contact

Kinetrol Actuator Feature Video

Here's a new Kinetrol vane actuator feature video. Please take a minute to watch. Hope you enjoy.

Pneumatic Actuators Well-suited for Offshore Valve and Damper Applications

|

| Offshore Platform |

Corrosion

|

| Corrosion resistant housing and sealed spring. |

Vibration

Constant structural vibration, caused by the dynamic forces generated by compressors, pumps, and engines, leads to poor equipment reliability and eventual failure. Pulsating and shaking forces expedite wear on mechanical connections such as gears and yoke mechanisms, with many gear failures due to resonant vibration.

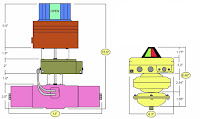

Space

Oil platform actuators, control valves, safety valves, and piping systems are configured very similarly to their terra firma cousins, with the major difference between land and platform equipment being reduced weight and size. Space is at a premium and it is critical to keep equipment as compact as possible.

|

| Single moving part. No gears or yokes. |

Kinetrol rotary vane actuators provide an excellent solution, well-suited for off-shore and marine applications. A durable epoxy stove enamel finish and corrosion resistant zinc (non-incendive) or aluminum alloy case protect the actuator from the harsh environment.

|

| Size comparison for similar output. |

Finally, Kinetrol vance actuators only require 1/3 to 1/2 the required installation space of similarly equipped rack and pion actuators.

For more information, contact Kinetrol USA by visiting https://www.kinetrolusa.com or calling 972-447-9443.

Vane, Shaft and Seal Design: The Critical Difference in Pneumatic Rotary Valve Actuators

|

| Click images for larger view. |

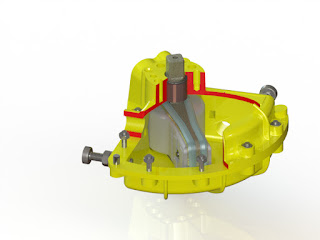

There are several manufacturers of pneumatic, rotary vane valve actuators on the market. Outwardly they appear similar. Internally, there's a world of difference in their design and their performance.

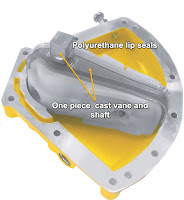

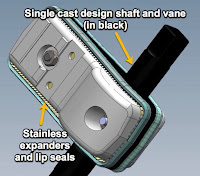

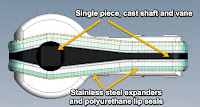

In higher quality vane actuators, the vane and shaft are machined from a single piece of steel. Casting and machining adds cost, but also adds performance. Lower quality actuators save cost by using a 2-piece vane/shaft combination. These are more likely to be affected by backlash or lost motion. In other words, a one-piece shaft and vane assembly transfers 100 percent of the vane movement directly to the shaft. Two-piece designs may lose movement over time, reducing control and accuracy.

In higher quality vane actuators, the vane and shaft are machined from a single piece of steel. Casting and machining adds cost, but also adds performance. Lower quality actuators save cost by using a 2-piece vane/shaft combination. These are more likely to be affected by backlash or lost motion. In other words, a one-piece shaft and vane assembly transfers 100 percent of the vane movement directly to the shaft. Two-piece designs may lose movement over time, reducing control and accuracy. Higher quality pneumatic vane actuators incorporate a pair of “lip seals” around the vane. The durable and resilient polyurethane seals provide two key benefits; eliminating the need for o-rings; and eliminating shaft seals. Dual, opposing lip seals are located each side of the vane. They isolate the vane and shaft from the air supply and create an area from the shaft through the center of the vane that remains unpressurized, eliminating the need for pressure seals around the top and bottom of the shaft.

Higher quality pneumatic vane actuators incorporate a pair of “lip seals” around the vane. The durable and resilient polyurethane seals provide two key benefits; eliminating the need for o-rings; and eliminating shaft seals. Dual, opposing lip seals are located each side of the vane. They isolate the vane and shaft from the air supply and create an area from the shaft through the center of the vane that remains unpressurized, eliminating the need for pressure seals around the top and bottom of the shaft.Some lower quality vane actuator designs use an o-ring around the entire vane, exposing the o-rings to mechanical stress and rolling. Higher quality actuators back their polyurethane lip seals with stainless steel expanders that maintain the integrity of the seal to the actuator housing.

The heart of the pneumatic vane actuator is simple design. Manufacturers often promote the concept of "a single moving part", referring to the vane/shaft/seal assembly. But despite this claim, all pneumatic vane actuators are not the same. You owe it to yourself and your organization to "look under the hood". See what level of engineering and quality you're really getting.

The heart of the pneumatic vane actuator is simple design. Manufacturers often promote the concept of "a single moving part", referring to the vane/shaft/seal assembly. But despite this claim, all pneumatic vane actuators are not the same. You owe it to yourself and your organization to "look under the hood". See what level of engineering and quality you're really getting.

How Kinetrol Pneumatic Rotary Vane Actuators Work

Kinetrol pneumatic rotary vane actuators use a one piece vane and shaft produce rotary torque on the shaft output drive. The vane is assembled inside a 2-piece clam-shell enclosure. The presence of the vane creates two air chambers. By pressurizing and venting opposing chambers, the resulting pressure differential across the vane provides torque to the shaft. Torque output of the rotary vane actuator remains constant throughout the full rotation of the shaft.

http://www.kinetrolusa.com | 972-447-9443

http://www.kinetrolusa.com | 972-447-9443

Kinetrol Pneumatic Actuators for Portland Cement Production

|

| Cement valve using Kinetrol Actuator |

Typically, these raw materials are obtained from open-face quarries, underground mines, or dredging operations. When mining, pockets of pyrite, which significantly increase emissions of sulfur dioxide (SO2), can be found in deposits of limestone, clays, and shales used as raw materials for portland cement.

Transport of the raw materials is accomplished by a variety of mechanisms, including screw

conveyors, belt conveyors, drag conveyors, bucket elevators, air slide conveyors, and pneumatic conveying systems. A variety of valves, gates, and dampers are required to accurately control the flow of raw materials as they are being discharged from pipes, silos, bins and hoppers. These flow control devices all have one thing in common - the actuators that control their opening and closing are exposed to extremely dusty and dirty atmospheres, with significant amounts of vibration - and they are almost always located in an area where repairs are very costly.

Kinetrol vane actuators are used to automate these gate, butterfly and mixer valves because of their ruggedness and their reliability. Additionally, Kinetrol pneumatic actuators have a smaller footprint and consume less air compared to other pneumatic actuators or conventional linear pneumatic cylinders, resulting in significant savings in energy costs.

Kinetrol USA Wishes the Food and Beverage Industry a "Blue Christmas"

|

| Kinetrol's Neil Meredith standing next to Kinetrol's "Blue Christmas Tree" (all the various size Blueline actuators stacked on top one another.) |

Finally, food and beverage producers have access to the excellent performance of the Kinetrol rotary vane actuators specially coated for use in the harsh wash-down environments common in the food industry. These actuators comply with the Federal Food, Drug and Cosmetic Act (FDA) and all applicable regulations, including 21 CR 175.300 (Code of Federal Regulations).

The actuators are intended to be installed in areas where harsh chemical wash-down is required. These areas are very tough on most types of pneumatic actuators because the caustic or acidic chemicals used in cleaning adversely effect the actuator.

For more information contact Kinetrol USA at http://www.kinetrolusa.com or call 972-447-9443.

14 Reasons to Choose the Kinetrol AP Pneumatic Valve Positioner

|

| AP postioner on Kinetrol actuator. |

- Enclosure and Lid – robust die-cast metal with tough corrosion-resistant epoxy coating and O-ring sealing. Layout gives easy access to all adjustments on removal of lid.

- Spool Valve – highly reliable, all metal, 5 port proportional valve controls the air flow. Three versions, with different flowrates, are easily interchangeable.

- Carrier Plate Assembly – integrated assemblies carrying the feedback shaft and cam plus angle retransmit drive and pot (when specified). Easily removed for conversion or maintenance.

- Interchangable Port Plate – easily convertible for different flowrate options.

- Feedback Pot Drive – zero backlash, proven trouble free for life.

- Retransmit Pot – high quality conductive plastic servo–type with ball bearings. Proven long life and high precision.

- Actuator Interface – options include NAMUR standard, Kinetrol male square or Kinetrol direct mount female square. Quick external conversion allows bracket mounting to any rotary or linear actuator.

- Internal Angle Scale – with adjustable indicator for easy field calibration.

- Exhaust Snubber Screws – allow travel speed reduction down to 1/ 3 x full speed, independently in each direction, by screwing in to restrict exhaust air flow.

- Gauge Port – as standard.

- Span and Zero Adjustment – quick and easy thumbwheel setting with slotted locking screw.

- Feedback Cam – quick and easy reversal ( for rotational sense handing) or replacement (to change the response characteristic) of the cam is facilitated by a spring loaded retention device.

- Feedback Shaft – innovative collet connection permits quick – fit/release of the actuator interface and eliminates backlash.

- Airflow Changeover Block – allows selection of direction in which positioner moves (for direct mount models).

Kinetrol Product Catalog October 2017

Most recent version of Kinetrol catalog including Blueline coating for foodservice applications. Kinetrol rotary vane actuators are used to operate or position ball, butterfly and plug valves, ventilation dampers and automatic doors. Uses also include movement and positioning of components during manufacture - in fact anything that needs to be turned through 90° or less, automatically or by remote control.

You can download the Kinetrol Product Catalog from the Kinetrol USA site here.

You can download the Kinetrol Product Catalog from the Kinetrol USA site here.

Labels:

actuation,

actuator,

automation,

food and beverage,

industrial,

valve

Kinetrol Actuators Performing Reliably Around the World

For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

Visit Kinetrol USA at http://www.kinetrolusa.com or call 972-447-9443.

Check out the video below for a sampling of the harsh applications where Kinetrol vane actuators thrive.

Labels:

biofuel,

chemical,

food & beverage,

gas,

metal,

mineral,

oil,

paper,

pharmaceutical,

power generation,

textile,

wastewater,

water

9 Kinetrol Features Providing Unmatched Actuator Performance

- Long life epoxy or PTFE internal finish

- Easy stop adjustment at each end of stroke for accurate seating

- Corrosion resistant zinc (non-incendive) or aluminium alloy case

- Integral vane/shaft casting - only one moving part

- Manual override square and position indicator

- Stainless steel expanders ensure long term lipseal / case contact

- Double opposed, Polyurethane, lip seals for effective sealing and long maintenance free life

- Space filling/energy absorbent sideplates (polymer or metal)

- Durable epoxy stove external enamel finish

Kinetrol USA - http://www.kinetrolusa.com | 972-447-9443

WEFTEC 2017

WEFTEC is recognized as the world’s largest annual water quality technical conference and exhibition, providing extensive educational opportunities and unparalleled access to the field’s most cutting-edge technologies and services.

Exhibition Details:

McCormick Place | Chicago, IL

Exhibition: October 2 - 4, 2017

Hours: 8:30 am - 5:00 pm daily

COME VISIT US AT BOOTH 4136

WEFTEC's expansive show floor provides unparalleled access to the most cutting-edge technologies in the field; serves as a forum for domestic and international business opportunities; and promotes invaluable peer-to-peer networking among registrants.

The conference provides insights and products for water and wastewater technologies including:

The conference provides insights and products for water and wastewater technologies including:

- Collection Systems - Management, operations and maintenance, infrastructure, overflow reduction, wet weather planning, watershed approaches, and regulations

- Energy Conservation and Management - Resource recovery, combined heat and power, biogas optimization

- Membrane Technologies - Application in wastewater and water reuse, innovations, enhanced performance, regulatory compliance

- Plant Operations and Treatment - Innovations, technologies, processes, and proven solutions in water and wastewater treatment; including nutrient removal and odor control

- Regulations - CMOM/SSO Rules, TMDL/Watershed Rules, Nutrient Trading, and NPDES Phase II

- Research - Leading edge process applications in water and wastewater treatment and recent developments

- Residuals & Biosolids - Incineration, disposal, reuse through land application, research, regulations, politics, and public perception

- Stormwater - Treatment, green infrastructure, wet weather management, modeling

- Utility Management - Asset Management and financial planning for infrastructure, technology, regulatory compliance, and security; including environmental management systems (EMS)

- Water Reuse/Recycling - Research, regulations, emerging technologies, proven processes

- Water Quality & Watershed Management - Stormwater, wet weather, and watershed issues

Kinetrol is exhibiting again this year and will be in booth 4136. Please come by and visit us if you attend.

McCormick Place | Chicago, IL

Exhibition: October 2 - 4, 2017

Hours: 8:30 am - 5:00 pm daily

COME VISIT US AT BOOTH 4136

This is a Great Chance to See the New Blueline Actuator for Food and Beverage Processing

Get a free pass to the PROCESS EXPO 2017 courtesy of Kinetrol USA!

September 19–22, 2017 • McCormick Place • Chicago, IL USA

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Stop by the Kinetrol booth #2670 and see the difference!

Instructions for your free pass: Visit this link and fill in your information. Or, go to the PROCESS EXPO 2017 site and use code 74768 when registering.

Control Valve Positioner and Control Valve Actuator Basics

|

| Control Valve Loop* |

Control valves control fluid in a pipe by varying the orifice size through which the fluid flows. Control valves contain three major components, the valve body, the positioner, and the valve actuator.

The valve body provides the fluid connections and movable restrictor comprised a valve stem and plug that is in contact with the fluid that varies the flow.

The valve body provides the fluid connections and movable restrictor comprised a valve stem and plug that is in contact with the fluid that varies the flow.

The valve actuator is the component that physically moves the restrictor to vary the fluid flow.

Their are two general categories of control valves - linear and rotary. Three actuator types are used in linear control valves including spring and diaphragm, solenoid, and motor operated. Three actuator types are used in rotary control valves including pneumatic, electric, and electro-hydraulic. Rotary actuators are sometimes referred to as "quarter-turn" or "partial-turn".

The valve disc (restrictor) controls flow through the valve body. A positioner receives information from a supervisory controller advising wether or not the flow condition is satisfactory. The positioner then provides a signal to the actuator that provides the force to open and close the valve.

Each type of positioner works in response to a process signal. Some positioners (linear) use a 3-15 PSI pneumatic process signal. The pressure is exerted on a large diaphragm creating downward force that is applied against a spring which moves the restrictor up and own. Other types of positioners use a 3-15 PSI pneumatic signal to regulate a higher supply pressure (such as 0-60 PSI) to move pistons or vanes back and forth (rotary).

The variable 3-15 PSI control signal can be provided directly by a pneumatic controller connected directly to the process, or in other cases the 3-15 PSI is regulated by an electropneumatic device called an I/P or E/P (current to pressure or voltage to pressure) transmitter. These transmitters receive their signal from a supervisory control as a 0-10VDC or 4-20mA and then throttle the 3-15 PSI output to open/close the valve.

* Image courtesy of Tony R. Kuphaldt from "Lessons In Industrial Instrumentation"

Pneumatic Actuators that Stand Up to Pulp and Paper Plants

|

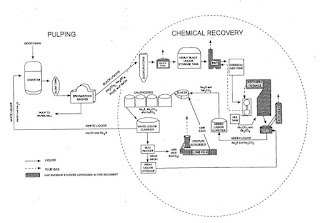

| Simplified Pulp and Paper Process Diagram |

The purpose of the chemical recovery cycle is to recover cooking liquor chemicals from spent cooking liquor. The process involves concentrating black liquor, combusting organic compounds, reducing inorganic compounds, and reconstituting cooking liquor.

|

| Chemical recovery process flow diagram. |

Decanted green liquor is transferred to the causticizing area, where the Na2CO3 is converted to NaOH by the addition of lime (calcium oxide [Ca0]). The green liquor is first transferred to a slaker tank, where Ca0 from the lime kiln reacts with water to form calcium hydroxide (Ca(OH)2). From the slake, liquor flows through a series of agitated tanks, referred to as causticizers, that allow the causticizing reaction to go to completion (i.e., Ca(OH)2 reacts with Na2CO3 to form NaOH and CaCO3).

Equipment used to produce pulp, paper, and paperboard is exposed to a wide range of temperature and humidity conditions, and contaminants. Actuators used in Pulp and Paper manufacturing processes must withstand the most difficult operating conditions. Kinetrol actuators are preferred in these situations because they don't allow corrosive atmospheres to penetrate the actuator or springs, their long cycle life, and their epoxy stove enamel finish.

Equipment used to produce pulp, paper, and paperboard is exposed to a wide range of temperature and humidity conditions, and contaminants. Actuators used in Pulp and Paper manufacturing processes must withstand the most difficult operating conditions. Kinetrol actuators are preferred in these situations because they don't allow corrosive atmospheres to penetrate the actuator or springs, their long cycle life, and their epoxy stove enamel finish.Contact the experts at Kinetrol USA at 972-447-9443 to discuss any pulp and paper mill actuator application.

PROCESS EXPO 2017 is Right Around the Corner!

Get a free pass to the PROCESS EXPO 2017 courtesy of Kinetrol USA!

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Stop by the Kinetrol booth #2670 and see the difference!

September 19–22, 2017 • McCormick Place • Chicago, IL USA

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations. Stop by the Kinetrol booth #2670 and see the difference!

Instructions for your free pass: Visit this link and fill in your information. Or, go to the PROCESS EXPO 2017 site and use code 74768 when registering.

Dampers and Louvers Used in Power Plants, Refineries, Boilers, and Furnaces

|

| Parallel damper with electric actuator. |

|

| Radial damper. |

|

| Pneumatic vane actuator damper drive. |

Radial-vane dampers use multiple vanes arranged like petals of a flower to throttle flow through a circular opening. A photograph of a radial-vane damper is shown here (note the levers and linkages on the periphery of the tube, synchronizing the motions of the eight vanes so they rotate at the same angle).

Dampers are opened and closed by electric or pneumatic drives. In recent years, the pneumatic vane actuator has earned an reputation for modulating dampers. Used in critical applications commonly found in power plants, refineries, boilers, and furnaces, these unique damper drives provide precise combustion gas management, are proven to increase boiler efficiency, lower fuel consumption, reduce emissions, and reduce maintenance cost.

Parts of this post are reprinted from Lessons In Industrial Instrumentation by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

New Blueline Section on Kinetrol USA Website

The Blueline Series actuators and spring return units with food grade coating have been added to the KinetrolUSA.com website.

More information can be found here - http://www.kinetrolusa.com/blueline.

More information can be found here - http://www.kinetrolusa.com/blueline.

Pneumatic Vane Actuators for Food Processing Applications

Blueline Actuators are permitted for use in contact with food in compliance with the Federal Food, Drug and Cosmetic Act (FDA) and all applicable regulations, including 21 CR 175.300 (Code of Federal Regulations).

For more information, call 972-447-9443 or visit http://www.kinetrolusa.com

Integral Vane-Shaft Actuators Best for High Cycle Rate and Modulating Applications

|

| Internal view of vane actuator. Note the single piece vane/shaft design. |

Why? Because of the mechanical problems inherent to the use of gears.

According to Wikipedia, "A gear or cogwheel is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part to transmit torque."

The primary disadvantages to gears are:

- Friction

- Fretting Wear

- Backlash

When gears mesh, there is friction. Friction causes heat and wear, which effects the mechanical life of the actuator. Friction converts kinetic energy into thermal energy and can have dramatic consequences if left unchecked. Another important consequence of friction is wear, which may lead to performance degradation and/or damage to the internal components of a rack and pinion or scotch yoke actuator.

"Fretting wear" is caused by the repeated cyclical rubbing between two surfaces (gears in the case of scotch yoke or rack and pinion actuators) and over a period of time, will remove material from one or both surfaces.

Backlash happens when gears change direction. It is caused by the gap between the trailing face of the driving tooth and the leading face of the tooth behind it. The gap must be closed before force can be transferred in the new direction, hence the phenomena of backlash. This is also sometimes referred to as "slop".

For pneumatic actuators with very low cycle rates, or ones that are not used for modulating service, internal gears may be acceptable. However, for applications where there are high cycle rates, or require accurate modulation, the use of a single machined vane actuator with integral shaft is preferred. The reason? No friction, wear, or backlash. 100 percent of the movement of the vane is transferred to the shaft without loss or hysteresis.

For any questions about applying the most appropriate type of actuator for any valve or damper application, call Kinetrol at 972-447-9443 or visit http://www.kinetrolusa.com.

Shark-Tested Rotary Vane Actuators

So what does a blog about rotary vane actuators have to do with Shark Week? The answer lies with the good people at MythBusters.

Out to prove (or disprove) the long-standing theory that punching a shark in the nose will scare it away, host Jamie Hyneman had to design a robotic shark punching machine that would deliver a powerful punch, similar to one that a real human being would deliver.

As they have in a past MythBuster episode, the MythBusters team turned to Kinetrol for the crucial piece of equipment - the Kinetrol pneumatic rotary vane actuator.

As they have in a past MythBuster episode, the MythBusters team turned to Kinetrol for the crucial piece of equipment - the Kinetrol pneumatic rotary vane actuator.The result was an underwater "Rock 'em Sock 'em Robot" machine with two arms, each powered by a Kinetrol Model 07 Actuator.

How Kinetrol Pneumatic Rotary Vane Actuators Work

Kinetrol pneumatic rotary vane actuators use a one piece vane and shaft produce rotary torque on the shaft output drive. The vane is assembled inside a 2-piece clam-shell enclosure. The presence of the vane creates two air chambers. By pressurizing and venting opposing chambers, the resulting pressure differential across the vane provides torque to the shaft. Torque output of the rotary vane actuator remains constant throughout the full rotation of the shaft.

Industrial Dampers and Drives

|

| Round dampers with pneumatic vane type drives. |

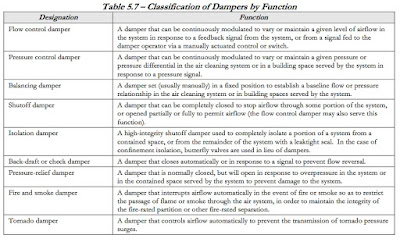

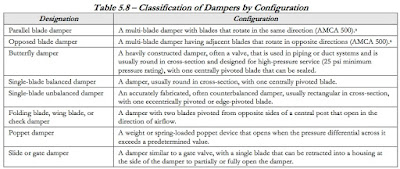

By definition, a damper is a device used to control pressure, flow, or flow direction in an air or gas system. Different types of dampers can be used, depending on specific functional requirements. Table 5.7 below lists the types of dampers and their functions, and Table 5.8 lists the damper configurations. Selection of the proper damper type and blade configuration is important to achieve the required damper performance. The type and configuration of damper can significantly impact pressure drop, leakage rates, and controllability.

|

| Click table for larger view. |

|

| Click table for larger view. |

|

| Pneumatic vane damper drive. |

A very important part of damper design is determination of damper torque and sizing and selection of damper actuator for the maximum torque. Actuator torque should be selected for a minimum of 1.5 times the damper maximum torque to provide margin and allow for degradation over the life of the damper. Actuators should be evaluated for damper blade movement in both directions, at the beginning of blade movement, and while stroking blades through the full cycle of movement.

Damper operators can be one of three types: pneumatic, electric, or electro-hydraulic, as described below.

- Pneumatic. These damper operators are used whenever controls rely primarily on compressed air (pneumatic) for moving operators or transmitting control signals.

- Electric. These damper operators are used whenever controls rely primarily on low voltage electric circuits to transmit control signals.

- Electrohydraulic. These damper operators are the same as the electric type described above, except they have the ability to modulate. They use an electric control signal to position a hydraulic system that, in turn, positions the damper.

Electrically operated damper drives have historically been favored, but the shift to retro-fit electric drives with pneumatic damper drives has been significant in the last two decades. When pneumatic vane actuators were first introduced for damper drive service, their virtues were quickly discovered. Their inherent design and operating advantages apply perfectly for precise damper control. These design and operating advantages are:

- Damper drives on round dampers.

- Precise, smooth signal to movement response.

- 100 percent duty cycle.

- Continuous modulating service.

- No overheating.

- High speed/high-torque.

- Fast full stroke open/close.

- Very easily serviced.

- Excels in harsh, high-temperature operating environments.

- Effectively zero air consumption in resting state.

For more information on any damper drive application, contact Kinetrol USA at 972-447-9443 or visit http://www.kinetrolusa.com.

Happy Fourth of July from Kinetrol

"We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable Rights, that among these are Life, Liberty and the pursuit of Happiness. — That to secure these rights, Governments are instituted among Men, deriving their just powers from the consent of the governed, — That whenever any Form of Government becomes destructive of these ends, it is the Right of the People to alter or to abolish it, and to institute new Government, laying its foundation on such principles and organizing its powers in such form, as to them shall seem most likely to effect their Safety and Happiness."

THOMAS JEFFERSON, Declaration of Independence

THOMAS JEFFERSON, Declaration of Independence

PROCESS EXPO 2017 Free Pass Courtesy of Kinetrol

Get a free pass to the PROCESS EXPO 2017 courtesy of Kinetrol USA!

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Stop by the Kinetrol booth #2670 and see the difference!

September 19–22, 2017 • McCormick Place • Chicago, IL USA

PROCESS EXPO is the nation’s largest trade show dedicated to bringing the latest technology and integrated solutions to all segments of the food and beverage industry.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations.

Kinetrol is featuring the new Blueline Actuator series specifically for the food and beverage industry. Kinetrol Blueline Rotary Vane Actuators provide a superior alternative for actuating quarter-turn valves in food and beverage applications and are guaranteed for up to 4 million operations. Stop by the Kinetrol booth #2670 and see the difference!

Instructions for your free pass: Visit this link and fill in your information. Or, go to the PROCESS EXPO 2017 site and use code 74768 when registering.

Pneumatic Actuator Application Guide for The Asphalt Industry

There are two main types of asphalt plants, batch and continuous. Batch plants are the most widespread and offer the greatest flexibility. Single batch mixes can be produced per each customer’s requirements. Individual components are weighed and metered separately every 50-60 seconds to produce a complete batch. Continuous plants produce single mix asphalt in large quantities without interruption. The production system is simplified, which reduces maintenance, but offers less flexibility.

The following Application Guide concentrates on batch plants, although similarities exist between both.

The following Application Guide concentrates on batch plants, although similarities exist between both.

You can read the guide below, or download it from Kintrol USA'a site here.

Kinetrol USA Exhibiting at Process Expo 2017

Kinetrol USA will exhibit it's pneumatic vane actuators for use in foodservice and beverage processing at Process Expo 2017.

Kinetrol USA will exhibit it's pneumatic vane actuators for use in foodservice and beverage processing at Process Expo 2017.

The exposition will be held on September 19–22, 2017 at McCormick Place in Chicago, IL.

Kinetrol's exhibit is located in the North Hall, booth #2670.

Kinetrol will be promoting it'd new "Blueline" actuator and accessories. The Blueline actuators are intended to be installed in areas where harsh chemical wash-down is required. These areas are very tough on most types of pneumatic actuators because the caustic or acidic chemicals used in cleaning adversely effect the actuator.

|

| Blueline actuator. |

Food and beverage processors from small to large companies across the globe attend PROCESS EXPO in Chicago, USA. Attendees cover a range of food production and manufacturing responsibilities including CEO, owner, corporate management, sales and marketing, production, operations, sanitation, maintenance, research and development, quality assurance, engineering, chefs, contract manufacturers, and more.

The attendees also represent a cross section of vertical markets in addition to manufacturers outside the food industry that can benefit from the machines, products, and safety issues covered at PROCESS EXPO. The vertical markets include:

- Bakery, Grains, Seeds, and Snacks

- Beverage

- Dairy

- Meat, Poultry, Seafood

- Prepared Foods, Fruits, Vegetables

- Confectionery, Candy, Sweets

- Pet Foods

Actuators for Ergonomic Moving and Lifting Equipment

Ergonomic manipulators (also know as ergo arms, articulating arms, articulating jib arms, and lift assist devices) are lifting assistance devices used to help workers lift, maneuver, and place items that are impossible to safely lift themselves.

Ergonomic lift assist devices increase productivity while offering an economic solution to material handling needs. They create a better way to work providing a safe and healthy workplace for employees, while increasing efficiency and productivity at the same time.

The Kinetrol vane actuator is an ideal pneumatic drive for industrial ergonomic manipulators due to:

Ergonomic lift assist devices increase productivity while offering an economic solution to material handling needs. They create a better way to work providing a safe and healthy workplace for employees, while increasing efficiency and productivity at the same time.

The Kinetrol vane actuator is an ideal pneumatic drive for industrial ergonomic manipulators due to:

- Compact size

- Powerful

- Wide range of torque outputs

- Exceptionally smooth control

Why Vane Actuators Are Better - We'll Make This Easy

With millions of actuators performing reliably around the world, the Kinetrol vane actuators' outstanding cycle life, smooth and precise movement, and environmentally rugged design makes it the best choice for all of your valve actuation needs.

The rotary vane actuator design is based upon a single moving part which eliminates

additional parts required to convert linear motion to rotary motion.

This simple and innovative design provides a highly accurate and

extremely reliable actuator for operating valves, drives and dampers,

and is perfectly suited for the most demanding process control control

applications.

Choosing the Right Valve Actuator for Pulp & Paper Processing

In pulp and paper mills there are many hazardous, corrosive and reactive chemicals used in the chemical pulping process. This particularly hostile atmosphere demands properly engineered automated valve systems and ruggedized valve actuators, spring units, and positioners.

If you understand the basics of how paper is made, and what chemicals are normally found in the environment, you'll understand immediately why special attention needs to be taken for valve and actuator selection.

In the early stage of paper production, during the separation of pulp from wood chips, digesters combine high heat and a strong alkaline liquid called "white liquor" to turn wood chips into pulp. The white liquor breaks down the lignin (the material that holds the wood fiber together) in wood chips and mixes with the white liquor to form a by-product referred to as "black liquor". Another by-product of this process is Hydrogen Sulfide, a poisonous, corrosive, and flammable gas.

|

| 8" valve on a green liquor line with Kinetrol Model 14 |

Black liquor is then sent to recovery boilers where molten solids - namely Sodium Sulfide, Sodium Carbonate - are formed. These molten solids are sent to tanks and mixed with water to become "green liquor".

While this phase of the process presents challenges to valve and actuator selection, the use of and exposure to harsh chemicals and compounds is not limited to the wood chip/pulp separation stage.

Later in the paper production process, the pulp is washed, screened and bleached. During this phase, valve actuators are exposed to atmospheres containing many other aggressive compounds such as Oxygen Chlorine, Hydrogen Peroxide, and Ozone.

Proper selection of valves and actuators is critical for worker safety, plant safety, and for the quality of the paper production. All components - valves, actuators, spring units, and positioners - need to be carefully selected to provide safe operation, redundancy, optimum control, and optimal service life.

Kinetrol products are designed for just such service and have an outstanding reputation in these applications. To find out how and why, visit http://www.kinetrolusa.com or call 972-447-9443.

Kinetrol products are designed for just such service and have an outstanding reputation in these applications. To find out how and why, visit http://www.kinetrolusa.com or call 972-447-9443.

Kinetrol Product Line Video

A short overview of the Kinetrol product line.

For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

Pneumatic Actuators Designed to Handle Food Processing Wash Down

|

| Self-foaming, caustic cleaners are applied to everything in the room. |

Many plants operate two 8-hour shifts, and reserve a third shift for a meticulous cleaning. During the cleaning shift, all equipment is locked out and tagged for safety, and then disassembled to provide access to all the small "nooks and crannies" where food and bacteria can hide. The next step involves a pre-rinse where any visible product debris is removed with hot water. Up next is the soap and scrub phase, where self-foaming general purpose cleaners are applied on all the equipment, walls, floors and drains of the production facility and then scrubbed with brushes and sponges.

It’s important to note that everything in the room is washed with these caustic and/or acidic cleaners.

The next step is typically another hot water wash-down, followed by careful visual inspections using flashlights to ensure all debris has been removed. The equipment is then re-assembled and swabbed with bioluminescence agents that glow when potential problem areas are found. Many processors go one step further and include a final step where they again flood the equipment, walls, and floor with cool water and more caustic sanitizer.

|

| Kinetrol Blueline for foodservice applications. |

Recently, Kinetrol introduced it's new “Blueline” pneumatic actuator which was tested and meets the requirements of 21 CFR 175.300. This new actuator stands up to the wash down chemicals used in plant cleaning making them available for use in areas where other pneumatic actuators are not approved, or simply can not stand up to the environment.

The Blueline Series provides food and beverage processors all the time-proven benefits of the Kinetrol PLUS provides an affordable option for tough chemical wash-down areas. For more information, visit Kinetrol USA's website or call 972-447-9443.

Boiler Damper Drives: Pneumatic Vane Actuators Excel

|

| Damper drive with pneumatic vane actuator (Kinetrol). |

|

| Damper drive (side mount) installed. |

|

| Damper drives on round dampers. |

- Precise, smooth signal to movement response

- 100 percent duty cycle

- Continuous modulating service

- No overheating

- High speed/high-torque

- Fast full stroke open/close

- Very easily serviced

- Excels in harsh, high-temperature operating environments

- Effectively zero air consumption in resting state

Subscribe to:

Posts (Atom)