“Cultivate the habit of being grateful for every good thing that comes to you, and to give thanks continuously. And because all things have contributed to your advancement, you should include all things in your gratitude.”

Ralph Waldo Emerson

The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Kinetrol is pleased to announce the introduction of the new Model 60 Actuator which will now increase the torque capability of the Kinetrol range to 356,977 inch pounds.

Kinetrol is pleased to announce the introduction of the new Model 60 Actuator which will now increase the torque capability of the Kinetrol range to 356,977 inch pounds. |

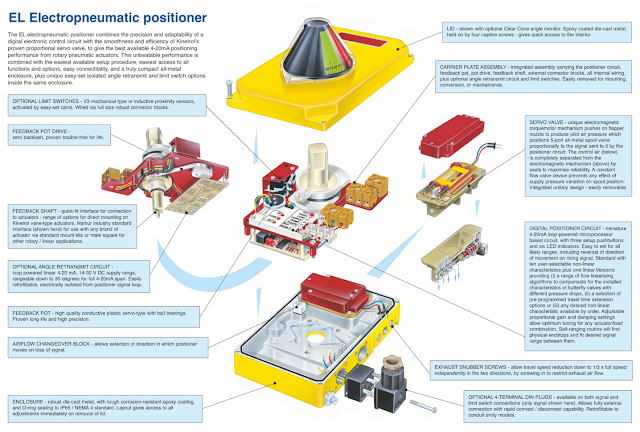

| Features of the Kinetrol EL positioner (click on image for larger view). |

|

| 6" ball valve with failing actuator. |

|

| The specified Kinetrol actuator and high Cv solenoid valve. |

|

| Hydraulic cylinder (shaded in yellow) and it's associated rods and yokes. Note the difficult access and adjustability. |

|

| Kinetrol actuator replacement. The actuator mounts directly to equipment, connected directly to the shaft eliminating the need for rods and yokes. |

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet.

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet. Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane.

Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane. Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms.

Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms. Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content.

Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content. Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges.

Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges. A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves.

A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves. |

| This picture is of what used to be a Kinetrol 097-120 and the valve it secured. |

|

| Close-up view of the Kinetrol Actuator. A melted ball of metal. |

The customer for this application note is an electrical power station with a combined-cycle, natural gas-fired generating unit with two combustion turbines, two heat recovery steam generators and one steam turbine. The output of combustion turbines can vary at different times throughout the year. The nominal output for this facility is 577 megawatts. The station burns natural gas.

The customer for this application note is an electrical power station with a combined-cycle, natural gas-fired generating unit with two combustion turbines, two heat recovery steam generators and one steam turbine. The output of combustion turbines can vary at different times throughout the year. The nominal output for this facility is 577 megawatts. The station burns natural gas. In this application, the customer had two 18" steam balancing valves using large, high torque, scotch-yoke actuators that had to cycle 20 times a day. These actuators presented significant performance issues (they were failing), plus they were very large which presented maintenance difficulties.

In this application, the customer had two 18" steam balancing valves using large, high torque, scotch-yoke actuators that had to cycle 20 times a day. These actuators presented significant performance issues (they were failing), plus they were very large which presented maintenance difficulties.