|

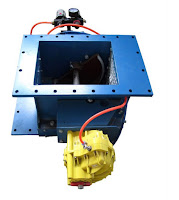

Kinetrol Actuator, Positioner and Spring on

Steam Line in Cheese Making Plant |

High above the cheese factory floor, mounted to a 1-1/2 steam supply pipe is a lonely V-ported ball valve with a Kinetrol 097-120 actuator, spring unit, and positioner. The valve is controlling 180 PSIG steam at 375 Deg. F. with the ambient air surrounding the actuator, positioner and spring unit at a constant 135 deg. F.

Its a tough application, and critical to keep running. Losing steam supply is very costly because of production losses and access to the valve is difficult.

The plant maintenance people tried a few of the more well-known valve/actuator packages without success. These packages would last a few weeks (a couple months at best), before failing. Frustrated and out of answers, the maintenance crew turned to a local Kinetrol Distributor salesperson for advice.

Knowing Kinetrol actuators, spring units and positioners are designed for the toughest applications, the salesperson specified the 097-120 on top of a Triad v-ported ball valve. Hopeful, but with little optimism, the maintenance crew installed the 1-1/2 control valve on the steam line and fired the system up.

For 11 months now (without any downtime), 24 hours a day, this lonely control valve, powered by a Kinetrol positioner and vane actuator, accurately throttles the steam supply and reliably keeps the cheese process line running.

Problem solved by Kinetrol!