The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Kinetrol Vane Actuators: The Optimal Solution for High Heat and Dust-Intensive Industrial Applications

Kinetrol USA

https://kinetrolusa.com

972-447-9443

Achieving Up to 4 Million Operations: The Efficiency of Kinetrol’s Rotary Actuator

In terms of cost, frequent replacements or repairs of actuators can lead to higher expenses over time. An actuator with a longer cycle life might have a higher initial cost, but its extended operational lifespan can minimize the need for frequent maintenance or replacement. By reducing the frequency of replacements and potential system downtimes, plants can maintain a more steady production rate and avoid unexpected costs related to equipment failure.

Safety is paramount in industrial settings, and an actuator's cycle life plays a role here, too. Actuators that don't achieve their expected cycle life can fail unexpectedly, potentially leading to uncontrolled valve movements. Such unpredictable behavior can harm personnel, the environment, and other equipment. For example, if a valve doesn't open or close as expected because of an actuator failure, it could release hazardous materials or create unsafe operating conditions in the plant.

Efficiency is another area where the cycle life of an actuator is crucial. When actuators on industrial quarter-turn valves operate consistently within their expected cycle life, they ensure the valves open and close as intended, allowing for the precise control of fluid flows. This accuracy is critical for maintaining optimal process conditions. When an actuator is nearing the end of its cycle life and begins to underperform, it can lead to inefficiencies, such as inaccurate flow rates or incomplete valve closures. These inefficiencies can affect product quality, yield, and overall system performance.

Kinetrol's claim of up to 4 million operations for its rotary actuator isn't just a mere statistic; it's a statement of endurance, reliability, and superior engineering. This impressive feat provides engineers and plant maintenance staff with undeniable advantages in terms of cost savings, enhanced safety, and operational efficiency when operating industrial valves.

In essence, Kinetrol's commitment to pushing the boundaries with their rotary actuator's impressive operational capacity isn't just an engineering achievement. It's a boon to the industries that rely on such equipment. Through cost savings, heightened safety, and enhanced efficiency, Kinetrol's rotary actuator stands as a testament to how advanced engineering can profoundly impact industrial operations.

Kinetrol USA

https://kinetrolusa.com

972-447-9443

The Steadyline Series: Kinetrol's Answer to Ultra-Reliable Valve Actuation with Enhanced Valve Damping Features

- Water Hammer: This is one of the most commonly known problems resulting from the rapid closing or opening of valves. Also known as hydraulic shock, water hammer occurs when a fluid's flow rate changes, causing a sudden increase in pressure producing shock waves that travel through the fluid in the pipes. The resulting forces can damage pipes, valves, and other equipment.

- Cavitation: This occurs when the pressure of a liquid drops below its vapor pressure, leading to the formation of vapor bubbles. When these bubbles move to an area of higher pressure, they collapse, causing localized shock waves, eroding the valves and pipes' material, and leading to premature equipment failure.

- Surge Pressures: Similar to water hammer but typically in systems with gases, rapid valve closure or opening can result in a pressure surge, damaging the system.

- Pump Issues: Rapidly closing a valve downstream of a pump can result in a sudden increase in pressure, which might cause the pump to work against a "dead head" condition, leading to overheating and potential damage to the pump.

- Instrumentation Errors: Rapid changes in flow rates can cause instrumentation reading errors, as many flow meters and sensors require steady-state conditions for accurate measurements.

- Process Upsets: Rapid valve actions can lead to unexpected changes in process conditions, potentially affecting product quality or even causing unsafe conditions.

- Noise: Fluids' sudden acceleration or deceleration can create noise due to vibrations. Over time, this can also contribute to material fatigue.

- Seal and Gasket Failure: The sudden change in pressure and flow can exert excessive stress on seals and gaskets, leading to premature failure.

- Mechanical Stress: The physical stress from rapid valve actions can weaken pipe supports, joints, and valve mechanisms.

Kinetrol USA

https://kinetrolusa.com

972-447-9443

Kinetrol Blueline Series: An Outstanding Choice for the Food and Beverage Industry

Kinetrol Blueline Coating Specification and Availability

- Models 03 to 18 Double Acting and Spring Return

- Positioners - EL and AP

- Switch boxes - VLS/ULS and Explosion Proof

- Resistance to "caustic washdown": The Blueline series works well in environments that frequently require caustic washdowns. The epoxy coating resists chemicals and aggressive cleaning agents, even under challenging conditions.

- Resistance to chipping/flaking: Durability is a hallmark of the Blueline series. The tough epoxy coating resists chipping and flaking, protecting the actuators and keeping them in prime condition over time.

- Non-stick properties: Hygiene is paramount in the food and beverage industry. The epoxy coating's non-stick properties make it easy to clean, preventing contaminants from adhering to the surface and contributing to a hygienic environment.

- Resistance to salt-laden environments: The Blueline series also suits applications with salt or salt-laden environments. The epoxy coating protects against corrosion and salt-induced deterioration.

- Visibility and detectability: If the coating ever dislodges, its bright sky-blue color is easy to spot. Sensors in food production can also detect the layer, ensuring quick identification and response to incidents.

Pneumatic Vane Actuators Revolution: Kinetrol's Blueline Series Designed for the Foodservice and Beverage Industry

https://KinetrolUSA.com

972-447-9443

Kinetrol Fire Fail-Safe Spring Units: An Important Solution for Valve and Damper Control in Fire Events

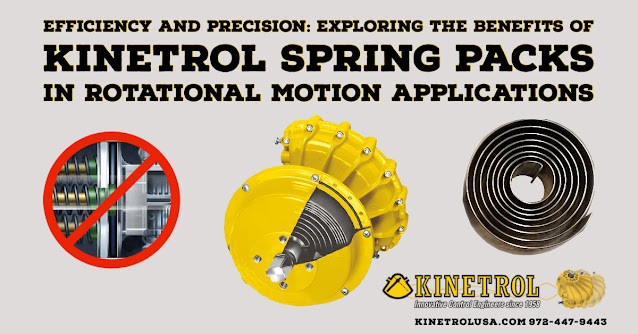

Kinetrol Spring Packs: Unleashing the Power of Advanced Torsion Spring Technology for Superior Performance

Torsion and helical compression springs are mechanical springs used for storing and releasing energy in various applications. However, in engineering terms, torsion springs perform better than helical compression springs for rotational motion due to their inherent design and functioning principles.

Torsion springs store and release rotational energy through the action of twisting. When a torsion spring twists, it stores potential energy in mechanical strain, which releases as the spring returns to equilibrium, allowing for a direct and efficient energy transfer in rotational applications.

On the other hand, helical compression springs are designed for linear motion and store energy when subjected to an axial compressive force. The spring compresses under load, storing potential energy as mechanical strain, and releases it as the spring returns to its uncompressed state. Due to their linear nature, helical compression springs are not as well-suited for rotational motion as torsion springs. Their energy transfer is less direct and efficient in these applications. Instead, they must include a rack and pinion mechanism for rotational movement. The use of these extra components introduces several disadvantages:

Disadvantages of helical compression springs for rotational movement:

- Increased complexity: The rack and pinion gear system adds complexity to the design, requiring additional components and maintenance compared to a torsion spring system.

- Lower efficiency: The energy transfer through the rack and pinion system is less direct and efficient, requiring converting linear motion from the helical compression spring into rotational motion.

- Backlash: The rack and pinion system may introduce backlash, which is the unwanted play between the gear teeth, potentially leading to imprecise motion control and increased wear over time.

- Space requirements: The additional components and assembly of the rack and pinion system require more space compared to a torsion spring, making it less suitable for compact applications.

Torsion springs outperform helical compression springs in rotational motion applications because their design and functioning principles allow for a more direct and efficient energy transfer. Torsion springs are better suited to meet the demands of rotational motion applications by storing and releasing energy through twisting rather than axial compression.

Kinetrol, a leader in precision-engineered mechanical components, manufactures highly reliable, low-stress, clock-type spring units for their broad line of pneumatic actuators and as stand-alone spring packs. Their "clock-type" design delivers unmatched reliability and performance, making them the preferred choice of mechanical engineers seeking to enhance efficiency and safety. These robust and resilient spring units can be seamlessly integrated into a wide range of non-Kinetrol applications, offering engineers the flexibility they require to address diverse design challenges. With their superior torsional characteristics, these spring packs are especially well-suited for applications such as spring return mechanisms and fail-safe operations, where consistent and dependable force output is paramount.

Advantage summary for Kinetrol Spring Packs:

- Angular force: Torsion springs exert a rotational or angular force, making them ideal for applications requiring rotational movement, such as quarter-turn actuators. On the other hand, helical compression springs exert a linear force, which is suitable for applications involving compression, but not for rotational motion.

- Space efficiency: Torsion springs can be more space-efficient than helical compression springs in specific applications. Their spiral design allows them to be compact and fit into tight spaces while providing the required force. It is advantageous in applications with limited space or the design demands a smaller footprint.

- Stability: Torsion springs can provide excellent stability in some applications, maintaining their force over a wide range of angular deflection allowing for more precise control and consistent performance in certain situations.

- No need for additional hardware: Torsion springs can apply force directly to the component they are working on without needing other hardware to accommodate rotational movement, simplifying the overall design and reducing the number of parts.

Kinetrol Actuators with Epoxy Stove Enamel Finish: A Winning Combination for Enhanced Durability and Style

Epoxy stove enamel external finish offers several advantages for various applications, primarily when used on high-heat equipment. Some of the key benefits of this type of finish include the following:

- Durability: Epoxy stove enamel finishes are known for their exceptional durability. They form a rugged, long-lasting, and abrasion-resistant surface that can withstand high temperatures and protect the underlying material from wear and tear, ensuring a longer lifespan for the equipment.

- Heat resistance: One of the primary advantages of epoxy stove enamel finishes is their ability to withstand high temperatures. These finishes can resist temperatures up to 500 degrees Fahrenheit (260 degrees Celsius) without degrading, peeling, or blistering, making them suitable for stoves and other high-heat equipment.

- Corrosion resistance: Epoxy stove enamel finishes offer excellent protection against corrosion and rust. The epoxy layer forms a barrier that prevents moisture, chemicals, and other environmental factors from reaching the underlying metal, ensuring the equipment stays in good condition for longer.

- Easy cleaning and maintenance: The smooth and non-porous surface of epoxy stove enamel finishes makes cleaning and maintenance a breeze. It does not easily attract dirt, grime, or grease and is cleanable with a damp cloth or mild cleaning solution, helping maintain a clean and hygienic cooking environment.

- Aesthetic appeal: Epoxy stove enamel finishes are available in various colors and finishes, allowing for customization and providing an attractive appearance to the equipment. The high-gloss and smooth finish enhances the appliance's look and gives it a premium feel.

- Chemical resistance: Epoxy coatings resist various chemicals, making them suitable for multiple environments. They can withstand exposure to household cleaners, food acids, and other substances without degrading or staining.

- UV resistance: The epoxy stove enamel finish offers protection against UV rays, preventing the color from fading or chalking over time. It ensures that the equipment maintains its appearance even when exposed to sunlight for prolonged periods.

- Environmentally friendly: Epoxy coatings are generally considered environmentally friendly. They do not emit harmful volatile organic compounds (VOCs) during curing, contributing to a healthier environment and improved indoor air quality.

In summary, an epoxy stove enamel external finish offers a range of advantages such as durability, heat and corrosion resistance, ease of cleaning and maintenance, aesthetic appeal, chemical and UV resistance, and eco-friendliness.

For more information, contact:

Kinetrol USA

https://kinetrolusa.com

972-447-9443