|

| Coal burning power plant |

|

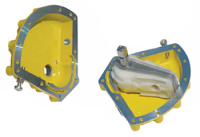

| Kinetrol Rotary Vane Actuator |

Its crucial that the double offset valves seat completely and are truly “zero-leakage”. In this high pressure and high abrasion scenario, even the slightest leak will cause a rapid failure of the valve seat.

Rack and pinion, scotch yoke, and electric actuators are problematic because of the inherent hysteresis in their gearing. This hysteresis compounds over time adding to the amount of error introduced and increasing the likelihood of a poorly closed valve.

Rotary vane actuators, on the other hand, provide “hysteresis-free” seating due to their single moving part and one piece vane and shaft design. When mounted to the butterfly valves with a no-play coupler, the valve disc is guaranteed to close tightly, without degradation over time.

Additional benefits of using the vane actuator is smooth, controlled closing to reduce the possibility of water hammer and the greater ability work in poor quality atmospheres, both of which are considerations for this application.