A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves.

A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves.A Midwestern power plant was experiencing failures with their filter's OEM rack and pinion actuators. The actuator cycle rate was moderate-to-high, approximately (1) cycle per hour, continuous.

While the cost of rack and pinion actuator replacement was relatively low, the cost of filter downtime and labor was very high for the utility. As part of an ongoing, long term cost savings effort, a more reliable and robust solution was required.

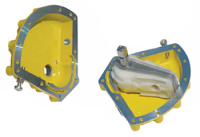

The local Kinetrol Distributor Salesperson was called in and immediately saw that replacing the rack and pinion actuators with Kinetrol vane actuators was the answer. Based on the countless applications around the world, where Kinetrol actuators perform reliably in the most challenging circumstances, this particular application was comparatively easy and straightforward.

The new Kinetrol actuators were retro-fitted to the existing valves with new mounting hardware and have been operating flawlessly for over a year now. Its expected the valves will wear out long before the actuators ever need service.

For more information about using Kinetrol vane actuators on filtration towers, contact Kinetrol USA by visiting https://kinetrolusa.com or by calling 972-447-9443.

Monoscour® is a registered trademark of Graver Water Systems.