Kinetrol actuators are well-known for their bright yellow, epoxy stove enamel finish. This coating is engineered to protect the exterior of their pneumatic actuators and accessories. But what is "epoxy stove enamel"?

Epoxy stove enamel is a high quality stoving finish that provides excellent adhesion to a substrate. Epoxy stove enamel forms a very hard, abrasion resistant, chemical and solvent resistant coating that stands up to many extreme environmental conditions. Epoxy stove enamel finish provides high level chemical/corrosion resistant qualities, and is used often in applications such as machinery, industrial equipment, and heavy duty transport machinery.

Kinetrol actuators are engineered specifically for high-cycle, dirty, and corrosive applications. The combination of epoxy stove enamel finish and stainless steel external hardware provide Kinetrol actuators outstanding protection from dirt and harmful chemicals.

Kinetrol USA

https://kinetrolusa.com

972-447-9443

The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Showing posts with label corrosive. Show all posts

Showing posts with label corrosive. Show all posts

Pneumatic Valve and Damper Actuators Designed to Stand Up to the Cement Industry

|

| Cement silos. |

Because of their reliability and ruggedness, Kinetrol rotary vane actuators are used in many processes across a cement plant. These applications include vehicle unloading, silo discharge, air cooling dampers, distribution, bagging and emissions control.

You can download a PDF that outlines where vane actuators are used in all areas of cement production here, or you can read the embedded document below.

Corrosive Flow Control Requirement? Use Thermoplastic Valves and Corrosion Resistant Rotary Actuators

|

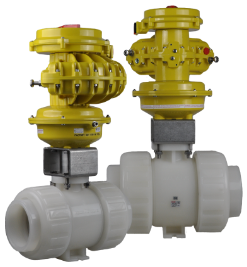

| Thermoplastic valves with corrosion resistant actuators, springs and positioners. (Kinetrol) |

Thoughtful actuator selection is required when plastic valves are specified. While the mechanics in applying pneumatic actuators to plastic quarter-turn valves is no different than metallic valves, the characteristics of the process and application can have significant impact on the performance the automated valve.

The assumption is that, if a thermoplastic valve is required, there is an higher probability the of exposure to corrosive media, or the automated valve assembly is located in a corrosive atmosphere, and therefore a corrosion resistant pneumatic actuator is preferred. Considering this, an actuator with internal and external parts protected by epoxy resins or special paints should be applied. Additionally, actuator spring systems should be designed in way to prevent exposure to corrosive media.

|

| Corrosion resistant rotary vane actuator with special external coating. (Kinetrol Blueline). |

The rotary vane actuators manufactured by Kinetrol standardly meet theses requirements. Engineered specifically for high-cycle, dirty, and corrosive applications, these very hardy, compact actuators come standardly with an epoxy stove enamel finish, stainless steel internal and external hardware, with spring units that are totally sealed from the atmospheric contaminants. For applications requiring greater corrosion resistance, such as caustic wash-down or salt-laden environments, an optional "Blueline" coating can be applied,

Rotary Vane Actuators for Corrosive Marine Environments: The Right Choice

|

| Corrosive marine environments present problems for valve actuators. |

Rotary vane actuators, (such as Kinetrol) provide strong immunity to internal corrosion. First, they have no internal gears or springs to corrode. Second, the internal surfaces are coated with a very durable, epoxy enamel finish and all internal hardware is made from stainless steel. Additionally, the “wiping” action of the vane and lip-seals provide a self-cleaning effect that prevents corrosion in the working areas. Finally, unlike rack & pinion and scotch-yoke actuators whose coil springs are bathed in ambient air, (Kinetrol) vane actuators use externally mounted clock type springs that are 100% sealed from ambient air/gasses and are unaffected by corrosive atmospheres.

For any application where corrosion is a problem, such as those in offshore platforms or other marine facilities, engineers should strongly consider rotary vane actuators as the preferred choice for any quarter-turn valve application.

The video below illustrates the difference in construction in actuator types and illustrates the inherent advantages of vane style actuators:

Pneumatic Actuators in Marine Environment (Offshore Rigs)

|

| High density, cramped spots are ideal for Kinetrol actuators and accessories. |

Because rotary vane actuators, (such as Kinetrol) or their spring units, don't "breathe" ambient air, they have great immunity to internal corrosion. Also, a very durable, epoxy enamel finish and stainless steel hardware provide maximum external protection.

|

| Ideal for corrosive, marine installation. |

Click on images for larger view.

|

| Low maintenance is important in hard to get to places |

|

| Long life where access is a problem. |

Subscribe to:

Comments (Atom)