The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Kinetrol Fire Fail-Safe Spring Units: An Important Solution for Valve and Damper Control in Fire Events

Kinetrol Spring Packs: Unleashing the Power of Advanced Torsion Spring Technology for Superior Performance

Torsion and helical compression springs are mechanical springs used for storing and releasing energy in various applications. However, in engineering terms, torsion springs perform better than helical compression springs for rotational motion due to their inherent design and functioning principles.

Torsion springs store and release rotational energy through the action of twisting. When a torsion spring twists, it stores potential energy in mechanical strain, which releases as the spring returns to equilibrium, allowing for a direct and efficient energy transfer in rotational applications.

On the other hand, helical compression springs are designed for linear motion and store energy when subjected to an axial compressive force. The spring compresses under load, storing potential energy as mechanical strain, and releases it as the spring returns to its uncompressed state. Due to their linear nature, helical compression springs are not as well-suited for rotational motion as torsion springs. Their energy transfer is less direct and efficient in these applications. Instead, they must include a rack and pinion mechanism for rotational movement. The use of these extra components introduces several disadvantages:

Disadvantages of helical compression springs for rotational movement:

- Increased complexity: The rack and pinion gear system adds complexity to the design, requiring additional components and maintenance compared to a torsion spring system.

- Lower efficiency: The energy transfer through the rack and pinion system is less direct and efficient, requiring converting linear motion from the helical compression spring into rotational motion.

- Backlash: The rack and pinion system may introduce backlash, which is the unwanted play between the gear teeth, potentially leading to imprecise motion control and increased wear over time.

- Space requirements: The additional components and assembly of the rack and pinion system require more space compared to a torsion spring, making it less suitable for compact applications.

Torsion springs outperform helical compression springs in rotational motion applications because their design and functioning principles allow for a more direct and efficient energy transfer. Torsion springs are better suited to meet the demands of rotational motion applications by storing and releasing energy through twisting rather than axial compression.

Kinetrol, a leader in precision-engineered mechanical components, manufactures highly reliable, low-stress, clock-type spring units for their broad line of pneumatic actuators and as stand-alone spring packs. Their "clock-type" design delivers unmatched reliability and performance, making them the preferred choice of mechanical engineers seeking to enhance efficiency and safety. These robust and resilient spring units can be seamlessly integrated into a wide range of non-Kinetrol applications, offering engineers the flexibility they require to address diverse design challenges. With their superior torsional characteristics, these spring packs are especially well-suited for applications such as spring return mechanisms and fail-safe operations, where consistent and dependable force output is paramount.

Advantage summary for Kinetrol Spring Packs:

- Angular force: Torsion springs exert a rotational or angular force, making them ideal for applications requiring rotational movement, such as quarter-turn actuators. On the other hand, helical compression springs exert a linear force, which is suitable for applications involving compression, but not for rotational motion.

- Space efficiency: Torsion springs can be more space-efficient than helical compression springs in specific applications. Their spiral design allows them to be compact and fit into tight spaces while providing the required force. It is advantageous in applications with limited space or the design demands a smaller footprint.

- Stability: Torsion springs can provide excellent stability in some applications, maintaining their force over a wide range of angular deflection allowing for more precise control and consistent performance in certain situations.

- No need for additional hardware: Torsion springs can apply force directly to the component they are working on without needing other hardware to accommodate rotational movement, simplifying the overall design and reducing the number of parts.

How To Install and Remove a Kinetrol Actuator Spring Unit

New Blueline Section on Kinetrol USA Website

More information can be found here - http://www.kinetrolusa.com/blueline.

New Product: Kinetrol Model 15 Spring Unit in Male and Female Drive

Kinetrol has just released the new Model 15 Spring Unit which consists of a new single spring in a sealed, non-breathing housing, rather than the Model 15*-0*0-5900 which consists of two model 14 springs.

The new spring design has significant benefits including over a 30% reduction in weight, over 25% reduction in the axial dimension and an increase in the pressure range from 3.5 Bar to 5.5 Bar.

The spring unit is available in both male and female drive (F14 with a 36mm A/F female square) and will retrofit to all Model 15 Actuators.

Kinetrol Spring Return Units: Spiral Torsion Springs Are Key

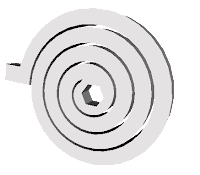

|

| Simple view of spiral torsion spring (protruding tab and hex center are loading points.) |

Capable of storing much more energy than a typical compression spring, and working in smaller, more compact packages, spiral torsion springs for valve and damper actuation are a proven step-up over helical compression springs.

When a torque is applied to a spiral torsion spring, an angular displacement is created between the first and second loading points, the coil deflects (tightens), and the spring material is placed under stress, exerting a linear (to the degree of rotation) rotational "output" torque, which drives the spring's rotation. Practically speaking, spiral torsion springs allow for lower torque loss, lower torque stress, and much greater reliability for use in valve and damper actuation.

|

| Kinetrol Spring Return Unit (note cutaway revealing spiral torsion spring.) |

- Separate housing for modular assembly, easily retrofitted

- Sealed, non-breathing housing: Protects spring in corrosive environments

- Adjustable pretension for 'balanced' air and spring stroke torques: Various combinations available for balanced / optimized torques at various air pressures

- Keeper plates available to ensure safe handling of pretensioned springs

- Available with ISO/DIN female drive and mounting

20" High Performance Butterfly Valve Closed in Under 1/2 Second!

|

| Fast closing Kinetrol actuator |

You'll note the valve takes about 11 seconds to open, but only 0.4 seconds to close, using the Kinetrol spring return unit.

Quick closing valves are used in emergency situations to stop the flow of fluids that may contribute to uncontrolled combustion, cause backstream contamination, or allow spillage of hazardous materials.

Kinetrol Solves the Toughest Pneumatic Actuator Challenges

Kinetrol provides a rugged, corrosion-resistant pneumatic vane actuator with only a single moving part.

This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control control applications.

The Kinetrol vane actuator is warranted to operate trouble-free for 4,000,000 (million) cycles.

For more information, contact:

KinetrolUSA

1085 Ohio Drive

Plano, Texas 75093

(972) 447-9443 phone

(972) 447-9720 fax

sales@kinetrolusa.com