A report released in June, from the security firm Dragos, describes a worrisome development by a hacker group named, “Xenotime” and at least two dangerous oil and gas intrusions and ongoing reconnaissance on United States power grids.

Multiple ICS (Industrial Control Sectors) sectors now face the XENOTIME threat; this means individual verticals – such as oil and gas, manufacturing, or electric – cannot ignore threats to other ICS entities because they are not specifically targeted.

The Dragos researchers have termed this threat proliferation as the world’s most dangerous cyberthreat since an event in 2017 where Xenotime had caused a serious operational outage at a crucial site in the Middle East.

The fact that concerns cybersecurity experts the most is that this hacking attack was a malware that chose to target the facility safety processes (SIS – safety instrumentation system).

For example, when temperatures in a reactor increase to an unsafe level, an SIS will automatically start a cooling process or immediately close a valve to prevent a safety accident. The SIS safety stems are both hardware and software that combine to protect facilities from life threatening accidents.

At this point, no one is sure who is behind Xenotime. Russia has been connected to one of the critical infrastructure attacks in the Ukraine. That attack was viewed to be the first hacker related power grid outage.

This is a “Cause for Concern” post that was published by Dragos on June 14, 2019.

“While none of the electric utility targeting events has resulted in a known, successful intrusion into victim organizations to date, the persistent attempts, and expansion in scope is cause for definite concern. XENOTIME has successfully compromised several oil and gas environments which demonstrates its ability to do so in other verticals. Specifically, XENOTIME remains one of only four threats (along with ELECTRUM, Sandworm, and the entities responsible for Stuxnet) to execute a deliberate disruptive or destructive attack.

XENOTIME is the only known entity to specifically target safety instrumented systems (SIS) for disruptive or destructive purposes. Electric utility environments are significantly different from oil and gas operations in several aspects, but electric operations still have safety and protection equipment that could be targeted with similar tradecraft. XENOTIME expressing consistent, direct interest in electric utility operations is a cause for deep concern given this adversary’s willingness to compromise process safety – and thus integrity – to fulfill its mission.

XENOTIME’s expansion to another industry vertical is emblematic of an increasingly hostile industrial threat landscape. Most observed XENOTIME activity focuses on initial information gathering and access operations necessary for follow-on ICS intrusion operations. As seen in long-running state-sponsored intrusions into US, UK, and other electric infrastructure, entities are increasingly interested in the fundamentals of ICS operations and displaying all the hallmarks associated with information and access acquisition necessary to conduct future attacks. While Dragos sees no evidence at this time indicating that XENOTIME (or any other activity group, such as ELECTRUM or ALLANITE) is capable of executing a prolonged disruptive or destructive event on electric utility operations, observed activity strongly signals adversary interest in meeting the prerequisites for doing so.”

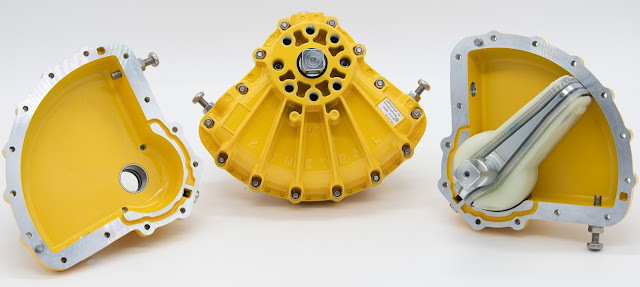

The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Kinetrol Vane Actuators in Sugar Production: Suger Cane Processing

First in a 2-part series on the use of Kinetrol pneumatic vane actuators in the production of sugar. The first part focusses on sugar cane processing. The second focusses on sugar beet processing.

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet.

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet.

Transportation – Cane is loaded into lorries or rail trucks and taken to the mills for processing. On arrival the cane is washed to remove rocks and leaves.

Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane.

Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane.

Milling – This is the extraction process whereby the sugar is removed from the cane. The shredded cane is crushed between heavy, grooved metal rollers to separate the juice from the fibre. The milling process involves a number of mills which are made up of three rollers arranged in a triangular formation. As the cane is crushed in the mills hot water (or recovered impure juice) is sprayed onto the crushed cane. The resultant dark green juice (sometimes called vesou) is then sent to a mixed juice tank for storage before clarification.

The cane fiber (called bagasse) is recycled as a fuel for the mill’s boiler furnaces. Importantly, milling must take place within 36 hours of the cane being cut.

Kinetrol units are used to control the flow of water to the spray system. It is necessary to ensure that sufficient water is used to remove the sugar content without flooding the cane.

Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms.

Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms.

Kinetrol units are used to control the flow of the vesou to the clarifier. Controlled flow reduces turbulence which allows for quicker settling times. Kinetrol's are also be used to control the recirculation flow of the sugar juice to the clarifier.

Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content.

Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content.

Kinetrol actuators are used to control the flow of steam to the evaporation tanks. In addition they control the flow of the juice through the evaporators. This is because of their reliability in the higher ambient temperatures in the process area.

Vacuum Pans – The syrup is concentrated further by boiling it in vacuum pans. Here it is ‘seeded’ with small sugar crystals to allow crystallization to take place. When the the sucrose concentration reaches the desired level the mixture of crystals and syrup, called massecuite, is sent to the centrifuges.

Kinetrol actuators control the input of heating steam into the pans as well as the flow of the massecuite through the process.

Centrifuges – High speed centrifuges separate the massecuite into sugar crystals and by-products (molasses).

Kinetrol actuators control the massecuite feeding system into the centrifuges. Accurate control of the valves feeding the centrifuges is necessary to prevent overloading and leakage of the centrifuges.

Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges.

Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges.

Dryers – Damp sugar crystals are dried in heated dryers before being sorted in sizes and either packed or stored.

Kinetrol's reliability, especially under hot, humid conditions, are crucial factors for our units being used within the sugar industry. Depending on the plant and location the actual ‘processing’ season varies from around four months for sugar beet to six months for sugar cane. During this short time it is essential that plants have no production issues as this will have a dramatic effect on the productivity and therefore competitiveness of the plant. The reliability and robustness of the Kinetrol units means they continue to function through each production season year after year.

Kinetrol’s ability to maintain an unchanged torque rating even with wear of the lip seals, means critical valves continue to function correctly over time. This is especially true with a product that is highly viscous in the later stage of production (e.g. thick juice, molasses).

With some plants being non-operational for many months of the year there does exist time for service & maintenance or replacement of rack & pinion actuators. However as margins within the sugar industry are low, the total cost of ownership for Kinetrol units over a number of production seasons makes them a more cost effective solution.

For more information, contact Kinetrol USA by calling 972-447-9443 or by visiting https://kinetrolusa.com.

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet.

Sugar is produced in over 130 countries worldwide. Around 80 percent of sugar is produced from cane, which is grown in tropical and sub-tropical regions. The remaining 20 percent is manufactured from beet grown in more temperate climates. Refined sugar is both chemically and functionally identical whether it is produced from cane or beet.Transportation – Cane is loaded into lorries or rail trucks and taken to the mills for processing. On arrival the cane is washed to remove rocks and leaves.

Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane.

Shredder – The shredder shreds the cane and reduces it into fibrous material to expose the sucrose bearing cells. This allows for the extraction (milling) process to maximize the removal of the sugar juice from the cane.Milling – This is the extraction process whereby the sugar is removed from the cane. The shredded cane is crushed between heavy, grooved metal rollers to separate the juice from the fibre. The milling process involves a number of mills which are made up of three rollers arranged in a triangular formation. As the cane is crushed in the mills hot water (or recovered impure juice) is sprayed onto the crushed cane. The resultant dark green juice (sometimes called vesou) is then sent to a mixed juice tank for storage before clarification.

The cane fiber (called bagasse) is recycled as a fuel for the mill’s boiler furnaces. Importantly, milling must take place within 36 hours of the cane being cut.

Kinetrol units are used to control the flow of water to the spray system. It is necessary to ensure that sufficient water is used to remove the sugar content without flooding the cane.

Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms.

Clarification and Filtering – Clarification is where soluble and insoluble impurities (sand, soil, etc.) are removed. The vesou is heated and then lime is added to the juice. Clear sugar juice is run off from the top of the clarifier. The muddy juice, extracted from the bottom of the clarifier, is mixed with fine bagasse and filtered to recover more sugar. This process can be repeated to ensure maximum recovery of sugar. The final recovered mud & bagasse mix is used as a soil treatment on the cane farms.Kinetrol units are used to control the flow of the vesou to the clarifier. Controlled flow reduces turbulence which allows for quicker settling times. Kinetrol's are also be used to control the recirculation flow of the sugar juice to the clarifier.

Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content.

Evaporation – The clear juice from the clarifier is concentrated into a syrup by boiling it under vacuum in evaporators. Around two-thirds of water in the juice is removed in the evaporation process leaving an end syrup with approximately 65-70 percent sugar content.Kinetrol actuators are used to control the flow of steam to the evaporation tanks. In addition they control the flow of the juice through the evaporators. This is because of their reliability in the higher ambient temperatures in the process area.

Vacuum Pans – The syrup is concentrated further by boiling it in vacuum pans. Here it is ‘seeded’ with small sugar crystals to allow crystallization to take place. When the the sucrose concentration reaches the desired level the mixture of crystals and syrup, called massecuite, is sent to the centrifuges.

Kinetrol actuators control the input of heating steam into the pans as well as the flow of the massecuite through the process.

Centrifuges – High speed centrifuges separate the massecuite into sugar crystals and by-products (molasses).

Kinetrol actuators control the massecuite feeding system into the centrifuges. Accurate control of the valves feeding the centrifuges is necessary to prevent overloading and leakage of the centrifuges.

Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges.

Kinetrol actuators also control the water inlets of the automated wash system for the centrifuges.Dryers – Damp sugar crystals are dried in heated dryers before being sorted in sizes and either packed or stored.

Kinetrol's reliability, especially under hot, humid conditions, are crucial factors for our units being used within the sugar industry. Depending on the plant and location the actual ‘processing’ season varies from around four months for sugar beet to six months for sugar cane. During this short time it is essential that plants have no production issues as this will have a dramatic effect on the productivity and therefore competitiveness of the plant. The reliability and robustness of the Kinetrol units means they continue to function through each production season year after year.

Kinetrol’s ability to maintain an unchanged torque rating even with wear of the lip seals, means critical valves continue to function correctly over time. This is especially true with a product that is highly viscous in the later stage of production (e.g. thick juice, molasses).

With some plants being non-operational for many months of the year there does exist time for service & maintenance or replacement of rack & pinion actuators. However as margins within the sugar industry are low, the total cost of ownership for Kinetrol units over a number of production seasons makes them a more cost effective solution.

For more information, contact Kinetrol USA by calling 972-447-9443 or by visiting https://kinetrolusa.com.

Changes to the Kinetrol VLS Limit Switch Box: KUSA-TSB123

After a decade since the launch of the Kinetrol Universal Limit Switch Box it has become necessary to replace the tooling. As a result, we have taken the opportunity to make some improvements to the design.

With the continued pressure for modularization and commonality the new precision die cast switch box will offer some positive improvements over the current model, more internal space for future developments and will be known as the VLS Limit Switch Box.

For more information, contact Kinetrol USA by calling 972-447-9443 or visit https://kinetrolusa.com.

With the continued pressure for modularization and commonality the new precision die cast switch box will offer some positive improvements over the current model, more internal space for future developments and will be known as the VLS Limit Switch Box.

For more information, contact Kinetrol USA by calling 972-447-9443 or visit https://kinetrolusa.com.

Kinetrol Vane Actuators

In addition, Kinetrol also manufactures a full range of positioners, limit switch boxes, fail-safe and fire fail-safe spring units, I to P transducers, spring-to-center 90° and 180° actuators, gearboxes and other engineered products from foundry to finished goods in our own ISO 9001-2008 certified factories.

Kinetrol is the inventor of the quarter turn pneumatic vane actuator and manufactures 16 sizes with torque outputs ranging from 8 lb inches to 168,000 lb inches when supplied with 100 psig.

Kinetrol’s exclusive direct-mount modular concept eliminates expensive and unnecessary tubing, fittings, brackets and couplings, which provides virtually hysteresis-free and extremely compact, automated assemblies. Unlike cylinder actuators, Kinetrol’s one piece vane and shaft design move as one resulting in extremely precise modulating and on/off control. Kinetrol actuators use double opposed polyurethane lip seals instead of O-ring seals typically used in quarter turn actuators. Kinetrol’s lip seal design isolates the shaft seal from plant air pressure and also acts as wiper for any foreign material which dramatically extends the service life of these actuators in all applications.

Knock off and copy attempts have come and gone over Kinetrol’s 60 plus year history, but none have come close to Kinetrol’s stellar track record of quality and reliability. Truth is in the performance and Kinetrol actuators have developed the reputation as the most reliable severe service, high cycle actuators the world over since 1958.

Kinetrol is the inventor of the quarter turn pneumatic vane actuator and manufactures 16 sizes with torque outputs ranging from 8 lb inches to 168,000 lb inches when supplied with 100 psig.

Kinetrol’s exclusive direct-mount modular concept eliminates expensive and unnecessary tubing, fittings, brackets and couplings, which provides virtually hysteresis-free and extremely compact, automated assemblies. Unlike cylinder actuators, Kinetrol’s one piece vane and shaft design move as one resulting in extremely precise modulating and on/off control. Kinetrol actuators use double opposed polyurethane lip seals instead of O-ring seals typically used in quarter turn actuators. Kinetrol’s lip seal design isolates the shaft seal from plant air pressure and also acts as wiper for any foreign material which dramatically extends the service life of these actuators in all applications.

Knock off and copy attempts have come and gone over Kinetrol’s 60 plus year history, but none have come close to Kinetrol’s stellar track record of quality and reliability. Truth is in the performance and Kinetrol actuators have developed the reputation as the most reliable severe service, high cycle actuators the world over since 1958.

Kinetrol USA

972-447-9443

Kinetrol Vane Actuators Lower Cost of Filter Operation at Power Plant

A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves.

A Monoscour® filter is a heavy duty, high-rate, gravity filter. It is designed for filtering high turbidity media and sticky particulates, and is commonly used in polymer chemical treatment, cooling tower side-stream filtration, and industrial wastewater filtering. This kind of filter is designed to be fully automatic and includes all piping and valves needed to change from filter mode to cleaning mode. Inexpensive rack and pinion actuators are installed as OEM components to divert flow between cycles. The actuators are mounted on 4" lug style butterfly valves.A Midwestern power plant was experiencing failures with their filter's OEM rack and pinion actuators. The actuator cycle rate was moderate-to-high, approximately (1) cycle per hour, continuous.

While the cost of rack and pinion actuator replacement was relatively low, the cost of filter downtime and labor was very high for the utility. As part of an ongoing, long term cost savings effort, a more reliable and robust solution was required.

The local Kinetrol Distributor Salesperson was called in and immediately saw that replacing the rack and pinion actuators with Kinetrol vane actuators was the answer. Based on the countless applications around the world, where Kinetrol actuators perform reliably in the most challenging circumstances, this particular application was comparatively easy and straightforward.

The new Kinetrol actuators were retro-fitted to the existing valves with new mounting hardware and have been operating flawlessly for over a year now. Its expected the valves will wear out long before the actuators ever need service.

For more information about using Kinetrol vane actuators on filtration towers, contact Kinetrol USA by visiting https://kinetrolusa.com or by calling 972-447-9443.

Monoscour® is a registered trademark of Graver Water Systems.

Even In the Hot Seat, Kinetrol Actuators Perform

|

| This picture is of what used to be a Kinetrol 097-120 and the valve it secured. |

A chemical manufacturer in the southeastern USA experienced a catastrophic fire in their compressor house 2014. The fire caused extensive damage to the facility and equipment, and shut down production for months. The compressor alone cost $30 million.

As part of the compressor safety shutdown system, two 6" Class 150 high performance butterfly valves with Kinetrol 097-120 actuators were installed on the process air lines. In the the event of an emergency, these valves needed to quickly close, and then stay closed, under any - and all - conditions.

|

| Close-up view of the Kinetrol Actuator. A melted ball of metal. |

Immediately upon activation of the emergency alarm, the two Kinetrol actuated assemblies received their signal and closed the valves quickly and tightly. As the fire raged, the actuators kept the valves secure, even after the extreme heat from the fire completely melted the actuator housings and internals.

As you can see from the pictures, the actuators were completely destroyed, but the valves stayed closed and and escalation of the emergency was prevented.

For more information, contact Kinetrol USA by calling 972-447-9443 or visit https://kinetrolusa.com.

Subscribe to:

Comments (Atom)