The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

From Digester to Recovery Boiler: How Kinetrol Actuators Deliver Reliability in Pulp and Paper Plants

Rugged Reliability: Kinetrol Actuators Thrive in Cement Plant Extremes

Harsh Conditions, No Downtime in a Cement Plant

Kinetrol’s rotary vane actuator (mounted under a cement hopper) and its VLS limit switch box endure layers of fine cement dust and constant equipment vibration while continuing to function flawlessly. In this Northern California cement plant, a gray film of cement powder coats every surface (as seen above), yet the Kinetrol actuator and limit switch keep performing with zero maintenance. Plant engineers cite these units as a rare “fit-and-forget” solution in an environment where most equipment struggles to survive.Maintenance-Free Design Built for Extremes

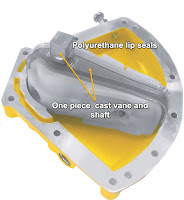

What makes Kinetrol actuators and their companion limit switch boxes so resilient in such harsh conditions? The answer lies in robust engineering and a simplicity of design purpose-built for longevity. Each rotary vane actuator contains only a single moving part – an integral vane and shaft – which means there are no delicate gears or multiple linkages to wear out or misalign. Fewer moving parts translate directly to higher reliability and very low maintenance. In fact, Kinetrol’s one-moving-part design is inherently a sealed system that keeps contaminants out. Double opposed polyurethane lip seals on the shaft serve as self-adjusting wipers that prevent dust ingress and maintain a tight seal over time. As the actuator cycles millions of times, these lip seals (backed by stainless steel spring expanders) continuously compensate for any wear, ensuring the internal components remain protected and pressurized air doesn’t leak.The VLS limit switch box shares the same rugged philosophy. Housed in a fully enclosed, die-cast metal casewith a corrosion-resistant epoxy coating, the VLS unit is sealed to IP67/NEMA 6 standards. This means that even the finest cement dust cannot penetrate the enclosure, and the internal switches and electronics remain clean and protected. The tight sealing also guards against moisture and grit, so the limit switches reliably indicate valve position without fouling or sticking. In practice, maintenance crews at the cement plant never need to open these switch boxes to clean them out – a stark contrast to lesser designs that might require frequent cleaning or gasket replacements in dusty service.

Real-World Proof of Long-Term Reliability

Kinetrol’s reputation for ruggedness isn’t based solely on one plant – it’s reinforced by countless applications across industries. For over 50 years, Kinetrol has been supplying “trouble-free” pneumatic rotary actuators to demanding sectors such as chemical processing, mining (mineral processing), oil and gas, power generation, and water treatment. In each case, the story is similar: the actuators simply keep working year after year, often outlasting the equipment around them. A plant engineer from another facility quipped that the Kinetrol units “last so long, we sometimes forget they’re even there until we notice everything else has needed maintenance except them.”Consider a case from the chemical industry: a southeastern US chemical plant installed a Kinetrol Model 187 actuator on a critical valve back in 1997. That actuator has been cycling every two minutes, 24/7, for decades – tallying over 5 million cycles – and it is still in service today. The original actuators (of a scotch-yoke design) that were on that valve had been failing due to seal leaks and jamming, but the Kinetrol replacement solved the reliability issues overnight. It’s a testament to Kinetrol’s engineering quality that even after nearly thirty years in a harsh process (processing reactor off-gas), the vane actuator remains operational with no major repairs.

Another example comes from a steelworks handling abrasive slurries. There, a Kinetrol spring-return actuator was paired with a butterfly valve to replace an earlier actuator that kept failing due to slurry ingress and wear. After months in operation, the new Kinetrol-driven valve showed no signs of wear and dramatically reduced maintenance needs. Such success stories have led many plants to adopt Kinetrol as their standard for critical valves and dampers. In the words of one plant manager, “We needed actuators that could survive literally anything – heat, dust, you name it. Kinetrol delivered, and we haven’t looked back.”

It’s not just marketing speak to call Kinetrol actuators “simply the best” in quarter-turn actuation – the industry has watched them perform where others failv. With an environmentally rugged design and outstanding cycle life, they have earned a loyal following. Even competitors’ engineers acknowledge the long service life and dependability of the Kinetrol units. As one distributor commented, “Kinetrol’s are great actuators and we love supplying them!”. This kind of praise underscores the broad confidence in Kinetrol’s ruggedness and engineering quality.

Conclusion: Engineering You Can Rely On

The cement plant in Northern California is a powerful demonstration of Kinetrol’s durability. In an environment that combines every possible stress factor – abrasive dust, high heat, continuous vibration, and round-the-clock operation – the Kinetrol standard pneumatic actuators and VLS limit switch boxes continue to excel with truly maintenance-free performance. Months and years pass with virtually no attention needed from the maintenance team, freeing them to focus on other equipment. The actuators stroke open and closed reliably, and the limit switches faithfully report positions to the control system without fail.For plant operators and engineers, this level of reliability translates into peace of mind and lower lifetime costs. There are no surprise shutdowns due to actuator failure, no weekly lubrication rounds, and no stockpile of replacement parts needed. Kinetrol’s “fit and forget” philosophy is more than a catchphrase – it’s a reality backed by decades of field experience and a design that prioritizes simplicity, strength, and seal integrity. When other actuators seize up or wear out under extreme conditions, Kinetrol units keep on turning. This exceptional longevity and ruggedness make Kinetrol actuators and VLS limit switches a smart choice for any operation where downtime is not an option and equipment must survive the harshest conditions. In short, if you need an actuator solution that laughs in the face of cement dust and heat, Kinetrol has proven time and again that it can deliver exactly that.

For professional industrial audiences looking for long-term reliability, the message is clear – when the going gets tough, Kinetrol actuators keep going, year after year, cycle after cycle, without maintenance and without fail.

Kinetrol USA

https://kinetrolusa.com

972-447-9443

Redefining Reliability: Kinetrol and the Makings of an Exceptional Brand

https://kinetrolusa.com

972-447-9443

Kinetrol Rotary Vane Actuators. Simply the Best.

Kinetrol rotary vane actuators have a well earned, and long established, reputation for performing where other pneumatic actuators fail. With outstanding cycle life, smooth and precise operation, and an environmentally rugged design, Kinetrol actuators are "simply the best" quarter-turn valve and damper actuator on the market today. Period.

For more information, contact Kinetrol USA. Call them at 972-447-9443 or visit their website at https://kinetrolusa.com.

The Top Five Reasons Why Kinetrol is a Better Choice Than Rack and Pinion Actuators

1. Rotary vane actuators do not convert linear motion to rotary motion, unlike rack and pinion actuators.

No additional gearing is required and no side loading is transferred to the actuator housing.

2. Vane actuator lip seals are the key for long life.

The double opposing lip seal design, with stainless steel expanders, provides unmatched service life by using air pressure to improve the actuators seal-to-enclosure contact, and provide a “self cleaning” effect on the epoxy or PTFE internal finish.3. The elimination of pressure bearing o-ring shaft seals.

Rack and pinion actuators require shaft sealing o-rings that are exposed to the full supply air pressure used to operate the actuator. These o-rings wear, causing leaks, a drop in efficiency, and wasted energy through air consumption. Vane actuators' double opposing lip seals isolate the supply air pressure from the actuator shaft, requiring only a low friction bearing on the shaft.4. Rotary vane actuators provide superior modulating accuracy.

Because of the integral vane and shaft (machine from a single casting), lost motion or hysteresis is reduced dramatically which intern provides much tighter modulation and control. The vane actuators inherent low friction also reduces hunting and sticking.5. Rotary vane actuator spring return units are designed to be virtually indestructible.

Using low stress, clock springs reduces spring tension loss and metal fatigue. The housing for vane a actuator springs are sealed from the atmosphere, preventing corrosion of internal parts. Most importantly, these type of spring units provide the lowest torque loss which enables the section of smaller (less expensive) actuators.Kinetrol USA

https://kinetrolusa.com

972-447-9443

The Most Reliable 1/4 Turn Pneumatic Actuator on the Market Today. Period.

Pneumatic Valve and Damper Actuators: A Design Comparison

Industrial valves, dampers and louvers are operated either electrically or pneumatically. This post compares the three major categories of pneumatic valve actuators, namely:

Industrial valves, dampers and louvers are operated either electrically or pneumatically. This post compares the three major categories of pneumatic valve actuators, namely:- Rotary vane

- Scotch-yoke

- Rack & pinion

All three can be configured in either direct acting or spring return versions. Direct acting actuators use the air supply to move the actuator in both directions (open and close). Spring return actuators, as the name implies, uses springs to move the actuator back to its "resting" state. Converting from direct acting to spring return is done through simple modifications, typically just adding an external spring module, or removing the end caps from rack and pinion actuators and installing several coil springs.

|

| Rotary Vane Actuator |

Rotary Vane Actuators

Vane actuators generally provide the most space savings when comparing size-to-torque with rack and pinion and scotch yoke. They have an outstanding reputation for long life because then contain only one moving part, as opposed to rack and pinion and scotch yoke actuators that have many. They tend to withstand dirty and corrosive atmospheres better than rack and pinion and scotch yoke actuators. Vane actuators also use externally mounted, helically wound "clock springs" for their spring return mechanism.

Scotch Yoke

Scotch Yoke

Scotch-yoke actuators use a pneumatic piston mechanism to transfer movement to a linear push rod, that in turn engages a pivoting lever arm to provide rotation. They come in a wide variety of sizes, but are very often used on larger valves because they are capable of producing very high torque output. Spring return units have a large return spring module mounted on the opposite end of the piston mechanism working directly against the pressurized cylinder.Rack and Pinion

A rack & pinion pneumatic actuator uses opposing pistons with integral gears to engage a pinion gear shaft to produce rotation. Rack & pinion actuators (sometimes referred to as a lunch box because of their shape) tend to be more compact than scotch yoke, have standardized mounting patterns, and produce output torques suitable for small to medium sized valves. They almost always include standard bolting and coupling patterns to directly attach a valve, solenoid, limit switch or positioner. Rack and pinion actuators use several smaller coil springs mounted internally and provide the torque to return the valve to its starting position.

A rack & pinion pneumatic actuator uses opposing pistons with integral gears to engage a pinion gear shaft to produce rotation. Rack & pinion actuators (sometimes referred to as a lunch box because of their shape) tend to be more compact than scotch yoke, have standardized mounting patterns, and produce output torques suitable for small to medium sized valves. They almost always include standard bolting and coupling patterns to directly attach a valve, solenoid, limit switch or positioner. Rack and pinion actuators use several smaller coil springs mounted internally and provide the torque to return the valve to its starting position.The practical difference between these three types of pneumatic actuators comes down to size, power, torque curve and ease of adding peripherals. For the best selection of valve actuator for any quarter turn valve application, you should seek the advice of a qualified valve automation specialist. By doing so your valve actuation package will be optimized for safety, longevity, and performance.

Scotch yoke mechanism image courtesy of Wikipedia.

Rack and pinion mechanism image courtesy of Wikipedia.

Kinetrol Actuator Feature Video

Vane, Shaft and Seal Design: The Critical Difference in Pneumatic Rotary Valve Actuators

|

| Click images for larger view. |

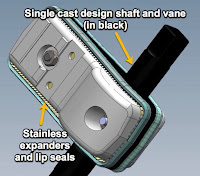

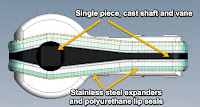

There are several manufacturers of pneumatic, rotary vane valve actuators on the market. Outwardly they appear similar. Internally, there's a world of difference in their design and their performance.

In higher quality vane actuators, the vane and shaft are machined from a single piece of steel. Casting and machining adds cost, but also adds performance. Lower quality actuators save cost by using a 2-piece vane/shaft combination. These are more likely to be affected by backlash or lost motion. In other words, a one-piece shaft and vane assembly transfers 100 percent of the vane movement directly to the shaft. Two-piece designs may lose movement over time, reducing control and accuracy.

In higher quality vane actuators, the vane and shaft are machined from a single piece of steel. Casting and machining adds cost, but also adds performance. Lower quality actuators save cost by using a 2-piece vane/shaft combination. These are more likely to be affected by backlash or lost motion. In other words, a one-piece shaft and vane assembly transfers 100 percent of the vane movement directly to the shaft. Two-piece designs may lose movement over time, reducing control and accuracy. Higher quality pneumatic vane actuators incorporate a pair of “lip seals” around the vane. The durable and resilient polyurethane seals provide two key benefits; eliminating the need for o-rings; and eliminating shaft seals. Dual, opposing lip seals are located each side of the vane. They isolate the vane and shaft from the air supply and create an area from the shaft through the center of the vane that remains unpressurized, eliminating the need for pressure seals around the top and bottom of the shaft.

Higher quality pneumatic vane actuators incorporate a pair of “lip seals” around the vane. The durable and resilient polyurethane seals provide two key benefits; eliminating the need for o-rings; and eliminating shaft seals. Dual, opposing lip seals are located each side of the vane. They isolate the vane and shaft from the air supply and create an area from the shaft through the center of the vane that remains unpressurized, eliminating the need for pressure seals around the top and bottom of the shaft.Some lower quality vane actuator designs use an o-ring around the entire vane, exposing the o-rings to mechanical stress and rolling. Higher quality actuators back their polyurethane lip seals with stainless steel expanders that maintain the integrity of the seal to the actuator housing.

The heart of the pneumatic vane actuator is simple design. Manufacturers often promote the concept of "a single moving part", referring to the vane/shaft/seal assembly. But despite this claim, all pneumatic vane actuators are not the same. You owe it to yourself and your organization to "look under the hood". See what level of engineering and quality you're really getting.

The heart of the pneumatic vane actuator is simple design. Manufacturers often promote the concept of "a single moving part", referring to the vane/shaft/seal assembly. But despite this claim, all pneumatic vane actuators are not the same. You owe it to yourself and your organization to "look under the hood". See what level of engineering and quality you're really getting.

How Kinetrol Pneumatic Rotary Vane Actuators Work

http://www.kinetrolusa.com | 972-447-9443

9 Kinetrol Features Providing Unmatched Actuator Performance

- Long life epoxy or PTFE internal finish

- Easy stop adjustment at each end of stroke for accurate seating

- Corrosion resistant zinc (non-incendive) or aluminium alloy case

- Integral vane/shaft casting - only one moving part

- Manual override square and position indicator

- Stainless steel expanders ensure long term lipseal / case contact

- Double opposed, Polyurethane, lip seals for effective sealing and long maintenance free life

- Space filling/energy absorbent sideplates (polymer or metal)

- Durable epoxy stove external enamel finish

Kinetrol USA - http://www.kinetrolusa.com | 972-447-9443

Dampers and Louvers Used in Power Plants, Refineries, Boilers, and Furnaces

|

| Parallel damper with electric actuator. |

|

| Radial damper. |

|

| Pneumatic vane actuator damper drive. |

Radial-vane dampers use multiple vanes arranged like petals of a flower to throttle flow through a circular opening. A photograph of a radial-vane damper is shown here (note the levers and linkages on the periphery of the tube, synchronizing the motions of the eight vanes so they rotate at the same angle).

Dampers are opened and closed by electric or pneumatic drives. In recent years, the pneumatic vane actuator has earned an reputation for modulating dampers. Used in critical applications commonly found in power plants, refineries, boilers, and furnaces, these unique damper drives provide precise combustion gas management, are proven to increase boiler efficiency, lower fuel consumption, reduce emissions, and reduce maintenance cost.

Parts of this post are reprinted from Lessons In Industrial Instrumentation by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

Shark-Tested Rotary Vane Actuators

So what does a blog about rotary vane actuators have to do with Shark Week? The answer lies with the good people at MythBusters.

Out to prove (or disprove) the long-standing theory that punching a shark in the nose will scare it away, host Jamie Hyneman had to design a robotic shark punching machine that would deliver a powerful punch, similar to one that a real human being would deliver.

As they have in a past MythBuster episode, the MythBusters team turned to Kinetrol for the crucial piece of equipment - the Kinetrol pneumatic rotary vane actuator.

As they have in a past MythBuster episode, the MythBusters team turned to Kinetrol for the crucial piece of equipment - the Kinetrol pneumatic rotary vane actuator.The result was an underwater "Rock 'em Sock 'em Robot" machine with two arms, each powered by a Kinetrol Model 07 Actuator.

How Kinetrol Pneumatic Rotary Vane Actuators Work

Industrial Dampers and Drives

|

| Round dampers with pneumatic vane type drives. |

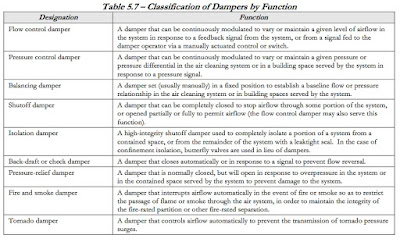

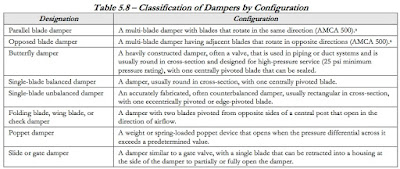

By definition, a damper is a device used to control pressure, flow, or flow direction in an air or gas system. Different types of dampers can be used, depending on specific functional requirements. Table 5.7 below lists the types of dampers and their functions, and Table 5.8 lists the damper configurations. Selection of the proper damper type and blade configuration is important to achieve the required damper performance. The type and configuration of damper can significantly impact pressure drop, leakage rates, and controllability.

|

| Click table for larger view. |

|

| Click table for larger view. |

|

| Pneumatic vane damper drive. |

Damper operators can be one of three types: pneumatic, electric, or electro-hydraulic, as described below.

- Pneumatic. These damper operators are used whenever controls rely primarily on compressed air (pneumatic) for moving operators or transmitting control signals.

- Electric. These damper operators are used whenever controls rely primarily on low voltage electric circuits to transmit control signals.

- Electrohydraulic. These damper operators are the same as the electric type described above, except they have the ability to modulate. They use an electric control signal to position a hydraulic system that, in turn, positions the damper.

- Damper drives on round dampers.

- Precise, smooth signal to movement response.

- 100 percent duty cycle.

- Continuous modulating service.

- No overheating.

- High speed/high-torque.

- Fast full stroke open/close.

- Very easily serviced.

- Excels in harsh, high-temperature operating environments.

- Effectively zero air consumption in resting state.

Why Vane Actuators Are Better - We'll Make This Easy

Lower Total-Cost-of-Ownership in Poor Process Environments with Pneumatic Vane Actuators

|

| Design advantages for use in poor process conditions (click for larger view). |

For the operation of pneumatically controlled valves, and as a better alternative to rack and pinion actuators, Kinetrol rotary vane actuators are an excellent choice. Their simple design, with one moving part, and an elegantly engineered vane, inherently protects the actuator from bad instrument air. Kinetrol's use of double opposed polyurethane lip seals, backed by stainless steel expanders, ensure long-term lip seal contact and effective sealing for years of maintenance free life. The vane, lip seals, and expanders actually provide a self-cleaning, or wiping, mechanism for any moisture, dirt or dust entering the interior of the actuator. In effect, the vane actuator's design "sweeps away" the debris that will cause other actuators to fail.

A considerable cost savings can be calculated given the trouble-free performance Kinetrol vane actuators provide. Assuming both a Kinetrol and standard rack and pinion actuator cost approximately the same, and that the life of a typical rack and pinion actuator in these environments is approximately 1 year, you can easily see the savings. By factoring in the replacement cost for an new actuator, and the cost of labor to install, you’ll find a standard rack and pinion is at least 2.5x the cost of Kinetrol over a 2 year period.

Kinetrol actuators have a well-earned reputation for operating trouble-free for years in the most difficult environments. Considering their years of maintenance-free service, it’s easy to understand the significantly lower total-cost-of-ownership they deliver.

For more information, visit Kinetrol USA at http://www.kinetrolusa.com or call 972-447-9443.

Avoid Fretting and Backlash with Rotary Vane Actuators

|

| Fretting and backlash shorten actuator life and negatively affects controllability over time. |

In pneumatic valve actuators, fretting wear is caused by the repeated cyclical rubbing between gears in scotch yoke or rack and pinion actuators. Over a period of time, fretting will remove material from one or both surfaces. This extra material, or debris, is usually harder than its source material due to work hardening and oxidation. The resulting debris becomes an even more effective abrasive, increasing the rate of mechanical wear and continued fretting.

Backlash happens when gears change direction. It is caused by the gap between the trailing face of the driving tooth and the leading face of the tooth behind it. The gap must be closed before force can be transferred in the new direction, hence the phenomena of backlash. This is also sometimes referred to as "slop".

Both fretting and backlash significantly effect the service life of an pneumatic valve or damper actuator. Both are also detrimental to controllability when actuators are used to accurately manage the percent open status of a valve or damper.

|

| Internal view of a rotary vane actuators. Notice the vane is constructed from a single piece of stock and contains no gears. |

For more information, visit http://www.KinetrolUSA.com or call 972-447-9443.

Rotary Vane Valve Actuators

|

| Rotary vane actuator |

Quarter turn valves are widely used in industrial process automation. Their application is primarily for operations requiring fully open or fully closed valve trim positions, although some do provide modulating service. A rotation of the valve stem through a 90 degree arc will reposition quarter turn valve trim between open and closed positions. A rotary vane actuator is well suited for driving this type of valve, with its own 90 degree arc of movement.

A rotary vane actuator operates quarter turn valves, dampers and louvers. A pressure tight housing contains a movable vane which is sealed to the sides of the pressure chamber by means of a low friction gasket. Inlets into the chamber on opposing sides of the vane allow a controller to produce a pressure differential across the vane. The vane will move, in response to the pressure differential, in either direction. A shaft is connected to the vane and the vane acts like a lever to rotate the shaft as the vane is moved by fluid pressure. The torque produced by the actuator assembly is primarily dependent upon the applied fluid pressure.

Hydraulic rotary vane actuators have the ability to handle large amounts of fluid and dynamic motions, exhibiting also qualities of durability and compactness. Pneumatic vane actuators use plant air pressure as the motive force. Both types generally have few moving parts and require little regular maintenance. A variety of typical automation accessories and options are available to customize a unit for a particular application.