|

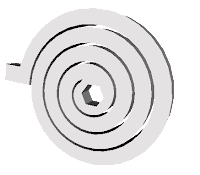

| Simple view of spiral torsion spring (protruding tab and hex center are loading points.) |

Capable of storing much more energy than a typical compression spring, and working in smaller, more compact packages, spiral torsion springs for valve and damper actuation are a proven step-up over helical compression springs.

When a torque is applied to a spiral torsion spring, an angular displacement is created between the first and second loading points, the coil deflects (tightens), and the spring material is placed under stress, exerting a linear (to the degree of rotation) rotational "output" torque, which drives the spring's rotation. Practically speaking, spiral torsion springs allow for lower torque loss, lower torque stress, and much greater reliability for use in valve and damper actuation.

|

| Kinetrol Spring Return Unit (note cutaway revealing spiral torsion spring.) |

- Separate housing for modular assembly, easily retrofitted

- Sealed, non-breathing housing: Protects spring in corrosive environments

- Adjustable pretension for 'balanced' air and spring stroke torques: Various combinations available for balanced / optimized torques at various air pressures

- Keeper plates available to ensure safe handling of pretensioned springs

- Available with ISO/DIN female drive and mounting

The combination of the spiral torsion spring reliability plus the advanced engineering design allow Kinetrol to offer a guarantee against failure of the spring unit for the lifetime of the mating actuator!

For more information, contact Kinetrol USA by visiting www.kinetrolusa.com or calling 972-447-9443.