For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

The Kinetrol rotary vane design is based upon a single moving part which eliminates additional parts required to convert linear motion to rotary motion. This simple and innovative design provides a highly accurate and extremely reliable actuator for operating valves, drives and dampers, and is perfectly suited for the most demanding process control applications. For more information visit www.kinetrolusa.com or call 972-447-9443.

Kinetrol Product Line Video

A short overview of the Kinetrol product line.

For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

For over 50 years Kinetrol has been providing trouble-free valve and damper actuators to the chemical, biofuel, food & beverage, metal, mineral, oil, gas, pharmaceutical, power generation, paper, textile, water, wastewater, and transportation industries.

Pneumatic Actuators Designed to Handle Food Processing Wash Down

|

| Self-foaming, caustic cleaners are applied to everything in the room. |

Many plants operate two 8-hour shifts, and reserve a third shift for a meticulous cleaning. During the cleaning shift, all equipment is locked out and tagged for safety, and then disassembled to provide access to all the small "nooks and crannies" where food and bacteria can hide. The next step involves a pre-rinse where any visible product debris is removed with hot water. Up next is the soap and scrub phase, where self-foaming general purpose cleaners are applied on all the equipment, walls, floors and drains of the production facility and then scrubbed with brushes and sponges.

It’s important to note that everything in the room is washed with these caustic and/or acidic cleaners.

The next step is typically another hot water wash-down, followed by careful visual inspections using flashlights to ensure all debris has been removed. The equipment is then re-assembled and swabbed with bioluminescence agents that glow when potential problem areas are found. Many processors go one step further and include a final step where they again flood the equipment, walls, and floor with cool water and more caustic sanitizer.

|

| Kinetrol Blueline for foodservice applications. |

Recently, Kinetrol introduced it's new “Blueline” pneumatic actuator which was tested and meets the requirements of 21 CFR 175.300. This new actuator stands up to the wash down chemicals used in plant cleaning making them available for use in areas where other pneumatic actuators are not approved, or simply can not stand up to the environment.

The Blueline Series provides food and beverage processors all the time-proven benefits of the Kinetrol PLUS provides an affordable option for tough chemical wash-down areas. For more information, visit Kinetrol USA's website or call 972-447-9443.

Boiler Damper Drives: Pneumatic Vane Actuators Excel

|

| Damper drive with pneumatic vane actuator (Kinetrol). |

|

| Damper drive (side mount) installed. |

|

| Damper drives on round dampers. |

- Precise, smooth signal to movement response

- 100 percent duty cycle

- Continuous modulating service

- No overheating

- High speed/high-torque

- Fast full stroke open/close

- Very easily serviced

- Excels in harsh, high-temperature operating environments

- Effectively zero air consumption in resting state

Lower Total-Cost-of-Ownership in Poor Process Environments with Pneumatic Vane Actuators

|

| Design advantages for use in poor process conditions (click for larger view). |

For the operation of pneumatically controlled valves, and as a better alternative to rack and pinion actuators, Kinetrol rotary vane actuators are an excellent choice. Their simple design, with one moving part, and an elegantly engineered vane, inherently protects the actuator from bad instrument air. Kinetrol's use of double opposed polyurethane lip seals, backed by stainless steel expanders, ensure long-term lip seal contact and effective sealing for years of maintenance free life. The vane, lip seals, and expanders actually provide a self-cleaning, or wiping, mechanism for any moisture, dirt or dust entering the interior of the actuator. In effect, the vane actuator's design "sweeps away" the debris that will cause other actuators to fail.

A considerable cost savings can be calculated given the trouble-free performance Kinetrol vane actuators provide. Assuming both a Kinetrol and standard rack and pinion actuator cost approximately the same, and that the life of a typical rack and pinion actuator in these environments is approximately 1 year, you can easily see the savings. By factoring in the replacement cost for an new actuator, and the cost of labor to install, you’ll find a standard rack and pinion is at least 2.5x the cost of Kinetrol over a 2 year period.

Kinetrol actuators have a well-earned reputation for operating trouble-free for years in the most difficult environments. Considering their years of maintenance-free service, it’s easy to understand the significantly lower total-cost-of-ownership they deliver.

For more information, visit Kinetrol USA at http://www.kinetrolusa.com or call 972-447-9443.

Rugged Design Makes This Vane Actuator the Best Choice for Any Valve or Damper Automation Job

Watch the video below for a quick understanding of why Kinetrol Vane Actuators provide the longest service life in the toughest valve and damper applications.

Proportional Spool Valve + Robust Force Balance Mechanism = Smooth and Accurate Control

|

| Kinetrol's AP pneumatic positioner. |

The result is a positioner with unparalleled performance and real industrial robustness, easy to calibrate and characterize, and adaptable to the whole range of applications with a great list of options:

- High flow valves

- Direct mount or industry standard discrete mount housings

- 4-20mA angle retransmit

- Limit switches

- Clear Cone position monitor

- I/P convertors (either simple or with various explosion proof options)

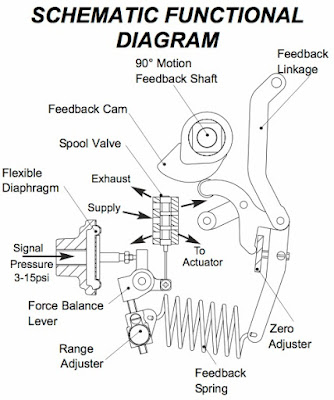

OPERATING PRINCIPLES

OPERATING PRINCIPLESThe AP positioner is designed to drive a rotary or linear actuator to a position set by a 3-15 psi (0.2-1.0 bar) signal and hold it there until the signal changes.

When a signal pressure is applied to the diaphragm it moves the force balance lever clockwise against the tension of the feedback spring. This moves the spool valve, supplying air pressure to one side of the actuator while exhausting trapped air from the other side. The feedback shaft follows the movement of the actuator and turns the cam counter clockwise, pushing the cam follower and increasing the tension on the feedback spring until it balances the force on the diaphragm and moves the spool valve to its central ‘hold’ position.

The relationship between the input signal and desired position (the ‘characteristic’) is determined by the cam profile. A linear 3-15 psi (0.2 - 1.0 bar) signal / 0-90° output movement cam is standard. Split range, fast opening, equal percentage or customized characteristic cams are available.

See the brochure below for detailed information and illustrations. For more information, contact Kinetrol USA at http://www.kinetrolusa.com or call 972-447-9443.

Subscribe to:

Comments (Atom)