Torsion and helical compression springs are mechanical springs used for storing and releasing energy in various applications. However, in engineering terms, torsion springs perform better than helical compression springs for rotational motion due to their inherent design and functioning principles.

Torsion springs store and release rotational energy through the action of twisting. When a torsion spring twists, it stores potential energy in mechanical strain, which releases as the spring returns to equilibrium, allowing for a direct and efficient energy transfer in rotational applications.

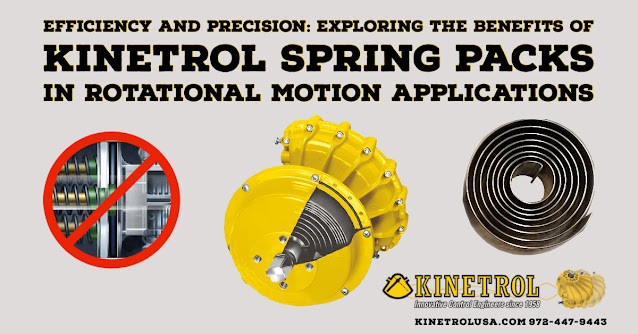

On the other hand, helical compression springs are designed for linear motion and store energy when subjected to an axial compressive force. The spring compresses under load, storing potential energy as mechanical strain, and releases it as the spring returns to its uncompressed state. Due to their linear nature, helical compression springs are not as well-suited for rotational motion as torsion springs. Their energy transfer is less direct and efficient in these applications. Instead, they must include a rack and pinion mechanism for rotational movement. The use of these extra components introduces several disadvantages:

Disadvantages of helical compression springs for rotational movement:

- Increased complexity: The rack and pinion gear system adds complexity to the design, requiring additional components and maintenance compared to a torsion spring system.

- Lower efficiency: The energy transfer through the rack and pinion system is less direct and efficient, requiring converting linear motion from the helical compression spring into rotational motion.

- Backlash: The rack and pinion system may introduce backlash, which is the unwanted play between the gear teeth, potentially leading to imprecise motion control and increased wear over time.

- Space requirements: The additional components and assembly of the rack and pinion system require more space compared to a torsion spring, making it less suitable for compact applications.

Torsion springs outperform helical compression springs in rotational motion applications because their design and functioning principles allow for a more direct and efficient energy transfer. Torsion springs are better suited to meet the demands of rotational motion applications by storing and releasing energy through twisting rather than axial compression.

Kinetrol, a leader in precision-engineered mechanical components, manufactures highly reliable, low-stress, clock-type spring units for their broad line of pneumatic actuators and as stand-alone spring packs. Their "clock-type" design delivers unmatched reliability and performance, making them the preferred choice of mechanical engineers seeking to enhance efficiency and safety. These robust and resilient spring units can be seamlessly integrated into a wide range of non-Kinetrol applications, offering engineers the flexibility they require to address diverse design challenges. With their superior torsional characteristics, these spring packs are especially well-suited for applications such as spring return mechanisms and fail-safe operations, where consistent and dependable force output is paramount.

Advantage summary for Kinetrol Spring Packs:

- Angular force: Torsion springs exert a rotational or angular force, making them ideal for applications requiring rotational movement, such as quarter-turn actuators. On the other hand, helical compression springs exert a linear force, which is suitable for applications involving compression, but not for rotational motion.

- Space efficiency: Torsion springs can be more space-efficient than helical compression springs in specific applications. Their spiral design allows them to be compact and fit into tight spaces while providing the required force. It is advantageous in applications with limited space or the design demands a smaller footprint.

- Stability: Torsion springs can provide excellent stability in some applications, maintaining their force over a wide range of angular deflection allowing for more precise control and consistent performance in certain situations.

- No need for additional hardware: Torsion springs can apply force directly to the component they are working on without needing other hardware to accommodate rotational movement, simplifying the overall design and reducing the number of parts.