|

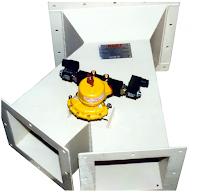

| Pneumatic rotary vane damper drive. |

In order to ensure efficient, reliable, and safe boiler operation, it is critical to accurately control the flow of the boiler's combustion air and flue gas. Poor control of airflow results in inefficient burning (wasting money), erratic cycling, flame-outs and even the possibility of toxic and hazardous emissions. In order to reduce the likelihood of these situations, accurate airflow control is critical.

In the United States, the Environmental Protection Agency's introduction of the MACT (Boiler Maximum Achievable Control Technology) Rule requires operators to institute maintenance procedures annually or bi-annually in an effort to force plant operators toward compliance. This strict new legislation has a large impact on how companies' control their emissions from industrial boilers, process heating systems and furnaces.

|

Typical drive applications and designs

(click for larger picture). |

Industrial boilers use dampers and louvers to control the quantity of air admitted to the furnace. Tighter boiler draft control significantly improves combustion. Any improvement in controlling the position of the dampers and increasing the positioning speed improves boiler efficiency. Damper operation needs to be precise and fast for the accurate control.

There are an estimated 15,000 boilers, furnaces, and process heaters running in the USA, and many are using an outdated primary component to control their lovers and dampers - the electric damper drive. Electric damper drives utilize motors and gear-boxes to move and position flue gas and combustion gas dampers. However, because of the inherent movement (sometimes referred to as hysteresis) between gears, linkages and other assorted mechanisms, these drives may not provide the accuracy, power, or signal response time required for optimum control.

Enter the pneumatic vane actuator damper drive. Pneumatic vane actuator drives are a newer, but still proven, method to provide high speed, accurate, and continuous modulation of air dampers for precise control. Replacing outdated electric damper drives with fast acting, pneumatic rotary vane damper drives offers measurable improvement to burner efficiency and cleaner emissions.

Switching out electric drives with their better performing pneumatic cousins is fairly simple. Downtime is not an issue. The old drive footprint, lever positions, connecting rods, and operational envelop are considered with every design. Any existing mechanical or electrical connection placements are matched. Since the new drive mates to all existing mounting and connections, and the envelope size is typically smaller, installing the pneumatic drive is usually a matter of pulling the old one out, and dropping the new one in.

At the heart of the pneumatic damper drive is the stalwart pneumatic rotary vane actuator. With hundreds of thousands of these devices operating in the toughest process applications around the world, their reputation is well earned. These actuators are known for their incredibly long life, ability to withstand very high cycle rates, and smooth “bump-less” control. They are also designed to handle high ambient temperatures, high vibration, and very dusty environments, typical of where boiler dampers are located. Additionally, rotary vane actuators are available with direct mount

pneumatic and

electro-pneumatic positioners,

manual overrides, network communication modules,

limit switches, and

spring modules. The direct mount design eliminates external brackets and coupling, and keeps the overall package size small.

Pneumatic vane actuator damper drives are a significant improvement over traditional electric damper drives. They provide fast response to input signal changes, very accurate positioning, a reduction in plant air consumption, and they lower fuel consumption. Engineers tasked with increasingly rigorous boiler emissions requirements must consider pneumatic vane style drives as a compelling alternative to the electric drive. They truly are an example of better form, fit, and function.