|

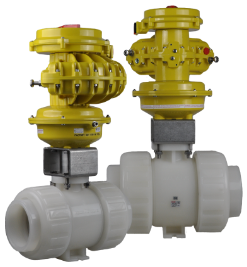

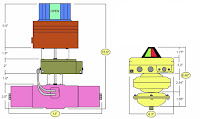

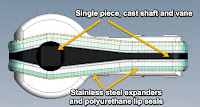

| Kinetrol vane actuator and dashpot assembly |

The "hammering" is due to a pressure wave created by the instantaneous change in fluid velocity when a valve is suddenly closed or opened. Controlling valve closure time is one of the most economical ways to minimize water hammer. To do this efficiently, while still meeting the process requirements, the use of a variable speed mechanism to control valve stroke is used. One unique, economical and space savings approach is to use a pneumatic vane actuator coupled with a rotary damper (or dashpot).

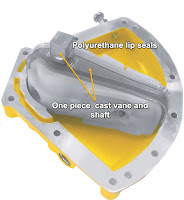

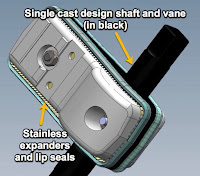

Rotary dashpots are precision fluid damping devices which give a smooth resistance to shaft rotation which increases with angular velocity.

In this case, a pump station in the USA was having repeated problems with a large, open reservoir hydraulic actuator used to dampen valve opening and closing. It was overly cumbersome and costly to maintain.

In its place, the pumping station installed Kinetrol Size 14 double acting actuators with digital speed controllers and Kinetrol LJ rotary dampers (with through-shafts to facilitate position feedback) installed on 12” Pratt butterfly valves.

In its place, the pumping station installed Kinetrol Size 14 double acting actuators with digital speed controllers and Kinetrol LJ rotary dampers (with through-shafts to facilitate position feedback) installed on 12” Pratt butterfly valves.The addition of the bi-directional, sealed dashpots smooth the normal travel, damp any valve flow induced disc oscillations, and provide at least 40 seconds travel time on air and/or electrical power failure.

Using pulsed outputs with programmable delay between steps, the actuators provide a 10 minute opening & closing time for the full 90 degree travel. The system is adjustable between 3-15 minutes with less than one degree increments., and other opening and closing ranges are available. The actuators use fail-free logic, but fail-hold & fail-safe are available.

These assemblies were commissioned in early Fall of 2017 and are working very well. Their use will be replicated at other pump stations operated by the same customer.

|

| This open reservoir hydraulic actuator was huge and a maintenance headache. |